Is pneumatic made of air?

Pneumatics is a branch of engineering and technology that deals with the mechanical properties of gases, typically focusing on the use of compressed air as a medium for power transmission and control. While the term "pneumatics" is related to air, it's not solely about air itself; rather, it's about the use of air (or other gases) as a medium to create mechanical motion, perform work, or control systems. In pneumatic systems, air is compressed and used to transmit energy and perform various tasks.

Key points about pneumatics:

Compressed Air: Pneumatic systems use compressed air, which is air that has been pressurized to a higher-than-atmospheric pressure. Compressed air is a readily available, safe, and cost-effective medium for many industrial and mechanical applications.

Applications: Pneumatic systems are used in various applications, including manufacturing, automation, transportation, and construction. They are often employed in tasks such as actuating cylinders, controlling valves, driving air tools, and powering pneumatic machinery.

Pneumatic Components: Pneumatic systems consist of components such as compressors (to generate compressed air), air reservoirs (to store compressed air), valves (to control the flow of air), actuators (such as cylinders), and various accessories.

Advantages: Pneumatic systems offer advantages such as simplicity, reliability, and safety. They are often chosen when precise control of motion is not critical, and when there is a need for high force or torque over short distances.

Not Exclusive to Air: While air is the most common gas used in pneumatic systems, other gases, such as nitrogen and carbon dioxide, can also be employed for specific applications.

In summary, pneumatics is not just about air but rather about the use of compressed gases, with air being the most common choice. Pneumatic systems are essential in many industries and applications, offering a versatile and practical means of transmitting energy and controlling mechanical processes.

Understanding Pneumatics: An Overview

Pneumatics is the study and use of compressed air to transmit power and energy. Pneumatic systems are used in a wide variety of applications, including industrial automation, robotics, and automotive systems.

How Pneumatic Systems Work

Pneumatic systems work by using compressed air to create force and motion. Compressed air is stored in a reservoir and then released to actuators, such as cylinders and motors. The actuators convert the compressed air energy into mechanical motion.

Components and Applications of Pneumatic Systems

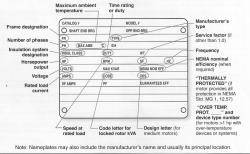

The main components of a pneumatic system are:

- Compressor: Compresses air to a high pressure.

- Reservoir: Stores compressed air.

- Valves: Control the flow of compressed air.

- Actuators: Convert compressed air energy into mechanical motion.

Pneumatic systems are used in a wide variety of applications, including:

- Industrial automation: Pneumatic systems are used to power robots, conveyors, and other industrial equipment.

- Robotics: Pneumatic systems are used to power the actuators in robots, allowing them to move and interact with their environment.

- Automotive systems: Pneumatic systems are used to power brakes, airbags, and other automotive systems.

Pneumatic vs. Hydraulic Systems

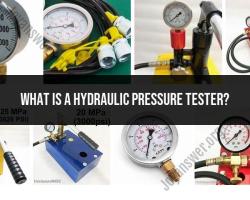

Pneumatic and hydraulic systems are both fluid power systems that use fluids to transmit power and energy. However, there are some key differences between the two systems.

Pneumatic systems use compressed air as the working fluid, while hydraulic systems use a liquid, such as oil or water. Pneumatic systems are typically less expensive and easier to maintain than hydraulic systems. However, hydraulic systems can generate more force and are better suited for applications where high power density is required.

The Role of Compressed Air in Pneumatics

Compressed air is essential to the operation of pneumatic systems. It is the compressed air that provides the force and motion to the actuators. Pneumatic systems can be powered by a variety of sources, such as air compressors, electric motors, and gasoline engines.

Compressed air also has a number of other advantages in pneumatic systems. It is clean, non-toxic, and easy to transport. It is also relatively inexpensive and readily available.

Conclusion

Pneumatic systems are a versatile and efficient way to transmit power and energy. They are used in a wide variety of applications, from industrial automation to robotics to automotive systems.