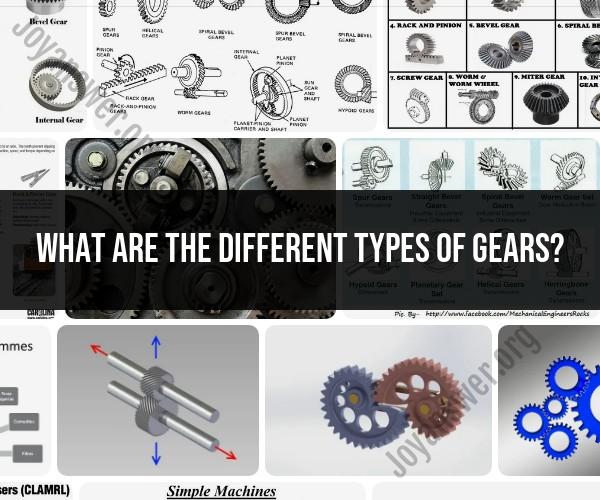

What are the different types of gears?

Gears are mechanical components that transmit motion and power between rotating shafts. They are widely used in machinery and mechanical systems for various purposes, including speed reduction, speed increase, torque multiplication, and direction reversal. There are several different types of gears, each with its unique characteristics and applications. Here are some of the most common types of gears:

Spur Gears:

- Spur gears are the most common type of gear and have straight teeth that are parallel to the gear's axis. They are used for speed reduction and speed increase applications and are known for their simplicity and efficiency.

Helical Gears:

- Helical gears have angled teeth that form a helix shape around the gear. They provide smoother and quieter operation compared to spur gears and can handle higher loads. Helical gears are often used in automotive transmissions.

Bevel Gears:

- Bevel gears have cone-shaped teeth and are used to transmit motion between intersecting shafts. They are commonly used in differential gears in vehicles and other machinery where shafts need to change direction.

Worm Gears:

- Worm gears consist of a screw-like gear (worm) and a toothed wheel (worm wheel). They provide high gear reduction ratios and are often used in applications where precision and slow speed are required, such as steering systems.

Planetary Gears:

- Planetary gears, also known as epicyclic gears, consist of a central sun gear, planetary gears that rotate around it, and an outer ring gear. They are used in various applications, including automatic transmissions and gearboxes.

Rack and Pinion Gears:

- Rack and pinion gears consist of a linear rack (a straight toothed bar) and a pinion gear. They are used to convert rotational motion into linear motion and are common in steering systems and CNC machines.

Internal Gears:

- Internal gears have teeth on the inside of the gear, and they mesh with external gears. They are used in applications where space constraints or specific design requirements necessitate an internal gear.

Spur Rack Gears:

- Spur rack gears are linear versions of spur gears. They have straight teeth and are used in applications requiring linear motion, such as conveyor systems.

Herringbone Gears:

- Herringbone gears have a double helix shape, which cancels out axial thrust forces and provides smooth operation. They are used in applications where high torque and precision are required.

Crown Gears:

- Crown gears are a type of bevel gear with teeth that form a crown-like shape. They are often used in differential mechanisms.

These are some of the most common types of gears used in mechanical systems and machinery. The choice of gear type depends on the specific requirements of the application, including speed, torque, direction, and space constraints. Gears are fundamental components in engineering and play a crucial role in a wide range of industries.