How do you calculate the power of a motor?

The power of a motor can be calculated using different methods and formulas depending on the information you have about the motor's characteristics and the specific application. Here are three common methods to calculate motor power:

Using Electrical Parameters:

If you have information about the electrical parameters of the motor, such as voltage (V) and current (I), you can calculate the electrical power (P_e) using the formula:

P_e = V x I

Where:

- P_e is the electrical power in watts (W).

- V is the voltage in volts (V).

- I is the current in amperes (A).

Keep in mind that this formula provides the electrical input power to the motor, which may not be the same as the mechanical output power due to losses in the motor.

Using Mechanical Parameters:

If you have information about the mechanical characteristics of the motor, such as torque (T) and rotational speed (ω), you can calculate the mechanical power (P_m) using the formula:

P_m = T x ω

Where:

- P_m is the mechanical power in watts (W).

- T is the torque in newton-meters (Nm).

- ω is the angular velocity in radians per second (rad/s).

This formula provides the mechanical output power of the motor, which is the power available to perform mechanical work.

Using Motor Efficiency:

Motors are not 100% efficient; they have losses that can include friction, heat, and electrical losses. To calculate the motor's power input based on its output, you can use the efficiency (η) of the motor:

P_e = P_m / η

Where:

- P_e is the electrical power input in watts (W).

- P_m is the mechanical power output in watts (W).

- η is the motor efficiency expressed as a decimal (e.g., 0.85 for 85%).

This formula accounts for the fact that not all electrical power input to the motor is converted into useful mechanical power output.

It's important to note that when calculating motor power for a specific application, you may need to consider additional factors such as load characteristics, duty cycle, and safety margins. Additionally, you might encounter power units other than watts, such as horsepower (1 horsepower is approximately equal to 746 watts), depending on your industry and region.

When working with motors, always refer to the motor's specifications and consult with experts or engineers if you have complex or specialized requirements, as motor calculations can become more intricate in practical applications.

Calculating Motor Power: A Comprehensive Guide

Motor power is the rate at which a motor converts electrical energy into mechanical energy. It is measured in watts (W) or horsepower (hp). The power rating of a motor is the maximum amount of power it can produce without overheating.

There are two main types of motor power: output power and input power. Output power is the mechanical power that the motor produces. Input power is the electrical power that the motor consumes.

To calculate motor power, you need to know the following information:

- Torque: The torque is the rotational force produced by the motor. It is measured in Newton-meters (Nm).

- Speed: The speed is the rotational speed of the motor. It is measured in revolutions per minute (rpm).

Formula for Calculating Motor Power

The following formula can be used to calculate motor power:

Output power = Torque * Speed

For example, a motor with a torque of 1 Nm and a speed of 1000 rpm has an output power of 1000 W.

Input Power

The input power of a motor is typically less than the output power, due to losses in the motor. The efficiency of a motor is a measure of how much of the input power is converted into output power.

The following formula can be used to calculate the input power of a motor:

Input power = Output power / Efficiency

For example, a motor with an output power of 1000 W and an efficiency of 80% has an input power of 1250 W.

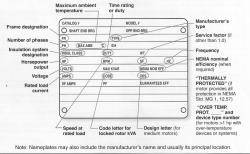

Determining the Power Rating of Electric Motors

The power rating of an electric motor is determined by its design and construction. The power rating is typically marked on the motor housing.

When choosing an electric motor, it is important to select a motor with a power rating that is equal to or greater than the required output power of the motor.

How to Calculate the Electrical Power of a Motor

The electrical power of a motor can be calculated using the following formula:

Electrical power = Voltage * Current

Where:

- Voltage is the voltage applied to the motor. It is measured in volts (V).

- Current is the current flowing through the motor. It is measured in amperes (A).

For example, a motor with a voltage of 120 V and a current of 10 A has an electrical power of 1200 W.

Conclusion

Calculating motor power is an important step in selecting and using electric motors. The power rating of a motor is the maximum amount of power it can produce without overheating. When choosing an electric motor, it is important to select a motor with a power rating that is equal to or greater than the required output power of the motor.