How to calculate torque for motor?

To calculate the torque required for a motor, you need to consider the mechanical load or application the motor is driving. The torque required depends on factors such as the type of load (e.g., rotational, linear), the distance from the motor's axis of rotation to the point of application (lever arm), and any additional forces acting on the load. Here are the basic steps to calculate torque:

Identify the Load Type: Determine the type of load the motor is driving. Is it a rotational load (e.g., a wheel, conveyor belt) or a linear load (e.g., a linear actuator, pulley system)?

Determine the Force or Weight: Find the force or weight that the motor needs to overcome or move. This force is usually measured in newtons (N) for SI units or pounds (lb) for imperial units. For example, if you are lifting a 100-pound weight, the force is 100 lb.

Calculate the Lever Arm: The lever arm is the perpendicular distance from the motor's axis of rotation to the point where the force is applied. Measure this distance in meters (m) for SI units or feet (ft) for imperial units. Let's say the lever arm is 0.5 meters (m).

Calculate Torque (Nm or lb-ft):

- For SI Units (Newton-meters, Nm): Torque (Nm) = Force (N) × Lever Arm (m)

- For Imperial Units (Pound-feet, lb-ft): Torque (lb-ft) = Force (lb) × Lever Arm (ft)

Let's use an example:

- Force (F) = 100 lb (pounds)

- Lever Arm (R) = 0.5 ft (feet)

Using the formula for torque in imperial units:Torque (lb-ft) = Force (lb) × Lever Arm (ft)Torque = 100 lb × 0.5 ftTorque = 50 lb-ft

So, in this example, a torque of 50 pound-feet (lb-ft) is required to lift the 100-pound weight at a lever arm of 0.5 feet from the motor's axis of rotation.

It's important to note that this is a simplified calculation and doesn't account for factors like friction, inefficiencies in the mechanical system, and dynamic loads, which can affect the actual torque requirements in real-world applications. Additionally, if the load is rotating, you may need to consider the moment of inertia of the load and its angular acceleration to calculate torque accurately in dynamic situations. In such cases, consulting with an engineer or using specialized software may be necessary.

Calculating Torque for Motors: A Comprehensive Guide

Torque is a rotational force that is applied to an object. It is measured in Newton-meters (Nm) or pound-feet (lb-ft). Torque is calculated by multiplying the force applied to an object by the distance from the axis of rotation.

Formula for calculating torque:

Torque = Force * Distance

For electric motors, torque is calculated using the following formula:

Torque = Kt * I

Where:

- Kt is the motor torque constant, which is measured in Nm/A.

- I is the current flowing through the motor windings, in amps.

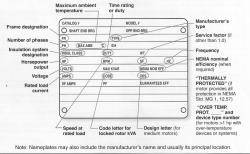

The motor torque constant is a measure of the motor's efficiency at converting electrical energy into mechanical energy. The higher the torque constant, the more torque the motor can produce per amp.

To calculate the torque for a motor, you need to know the motor torque constant and the current flowing through the motor windings. The motor torque constant can be found in the motor's datasheet. The current flowing through the motor windings can be measured using a clamp meter.

Example:

A motor has a torque constant of 0.25 Nm/A and the current flowing through the motor windings is 10 amps. The torque of the motor is calculated as follows:

Torque = Kt * I

Torque = 0.25 Nm/A * 10 amps

Torque = 2.5 Nm

Determining Torque Values for Electric Motors

The torque of an electric motor can be determined by measuring the current flowing through the motor windings and using the following formula:

Torque = Kt * I

Where:

- Kt is the motor torque constant, which is measured in Nm/A.

- I is the current flowing through the motor windings, in amps.

The current flowing through the motor windings can be measured using a clamp meter.

How to Compute Torque in Motor Applications

The torque required for a motor application can be calculated using the following formula:

Torque = Power / Speed

Where:

- Power is the power required for the application, in watts.

- Speed is the speed required for the application, in revolutions per minute (RPM).

Once you have calculated the required torque, you can choose a motor with a torque rating that is greater than or equal to the required torque.

Here are some additional tips for calculating torque for motors:

- Make sure to use the correct units in the torque formula. Torque is measured in Newton-meters (Nm) or pound-feet (lb-ft).

- If you are using a calculator to calculate torque, make sure that the calculator is in the correct mode. Most calculators have a torque mode that can be used to calculate torque in Nm or lb-ft.

- If you are unsure about the torque requirements for your application, it is best to consult with a motor engineer.