Why is there always uncertainty in every measurement?

There is always uncertainty in every measurement due to a combination of factors, and these factors arise from the limitations of both the measurement process and the physical world. Here are some key reasons why measurement uncertainty is inherent in all measurements:

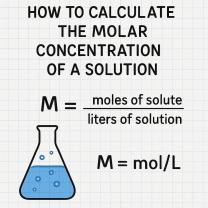

Instrument Limitations: All measurement instruments have limitations in terms of precision and accuracy. The smallest division or resolution of an instrument sets a lower bound on the precision of measurements. For example, a ruler with millimeter markings cannot measure lengths to a precision greater than one millimeter.

Calibration Uncertainty: Instruments need to be calibrated to ensure accuracy. However, the calibration process itself introduces uncertainty, and there may be slight variations between instruments, even after calibration.

Environmental Conditions: Measurements can be affected by variations in temperature, humidity, pressure, and other environmental factors. These factors can cause instruments to drift or affect the properties of the substance being measured.

Human Error: Human operators are not infallible. Factors such as parallax error, reading errors, and variations in technique can introduce uncertainty into measurements.

Random Variability: Many measurements involve inherently variable systems. For example, in physics, quantum mechanics dictates that certain properties of particles, like their position and momentum, cannot be precisely determined simultaneously due to the inherent randomness at the quantum level.

Sampling Error: When measurements are taken from a sample of a larger population or system, there is always a chance that the sample does not perfectly represent the entire population, leading to sampling error.

Systematic Errors: These are consistent biases or inaccuracies introduced by the measurement system or method. They can be caused by factors such as imperfect calibration, equipment malfunctions, or incorrect assumptions in the measurement model.

Limitations of Mathematics: Some quantities are inherently irrational or transcendental, and their values cannot be expressed precisely in decimal or fractional form. For example, the value of pi (π) or the square root of 2 (√2) are examples of such quantities.

Uncertainty Principle: In quantum physics, Heisenberg's Uncertainty Principle states that certain pairs of physical properties, like position and momentum, cannot be simultaneously measured with arbitrary precision. This principle is a fundamental aspect of the behavior of subatomic particles.

In practice, the goal of measurement science and metrology is to quantify and minimize measurement uncertainty to the greatest extent possible. This is achieved through calibration, error analysis, statistical methods, and the use of advanced measurement instruments and techniques. While perfect precision and accuracy are unattainable, understanding and managing measurement uncertainty allows for reliable and meaningful comparisons and conclusions in scientific research, engineering, industry, and everyday life.

Exploring Uncertainty in Measurement: Causes and Implications

Uncertainty in measurement is the doubt that exists about the result of any measurement. It is caused by a variety of factors, both systematic and random.

Systematic errors are constant or predictable errors that can be corrected for. Examples of systematic errors include:

- Calibration error: This is the error caused by the measuring instrument not being properly calibrated.

- Environmental effects: This is the error caused by environmental factors such as temperature, humidity, and vibration.

- Observer error: This is the error caused by the person performing the measurement.

Random errors are unpredictable errors that cannot be corrected for. Examples of random errors include:

- Environmental noise: This is the error caused by random fluctuations in the environment, such as air currents and electrical noise.

- Variation in the product being measured: This is the error caused by the fact that no two products are exactly alike.

Uncertainty in measurement can have a significant impact on the results of a measurement. For example, if the uncertainty in the measurement of the weight of a product is too high, it could lead to the product being over or under-packaged.

Sources of Error and Variability in Measurement

There are a number of different sources of error and variability in measurement. Some of the most common sources include:

- The measuring instrument: This includes the accuracy and precision of the instrument, as well as the calibration of the instrument.

- The environment: This includes factors such as temperature, humidity, and vibration.

- The operator: This includes the skill and experience of the person performing the measurement.

- The product being measured: This includes factors such as the size, shape, and material of the product.

Managing and Mitigating Uncertainty for Accurate Results

There are a number of things that can be done to manage and mitigate uncertainty in measurement. These include:

- Using calibrated and accurate measuring instruments: This is essential for reducing systematic error.

- Controlling the environment: This includes factors such as temperature, humidity, and vibration.

- Training and supervising operators: This is important for reducing operator error.

- Taking multiple measurements and averaging the results: This can help to reduce random error.

- Using statistical methods to analyze the data: This can help to identify and quantify the sources of uncertainty in the measurement.

By managing and mitigating uncertainty, it is possible to achieve more accurate and reliable measurement results.

Here are some additional tips for reducing uncertainty in measurement:

- Use a measuring instrument that is appropriate for the task at hand. Make sure that the instrument has the required accuracy and precision.

- Follow the manufacturer's instructions for operating the measuring instrument.

- Take multiple measurements and average the results. This will help to reduce random error.

- Be aware of the sources of uncertainty in your measurement. Take steps to control these sources of uncertainty whenever possible.

- Report the uncertainty along with the measurement result. This allows others to understand the reliability of the result and make informed decisions based on it.