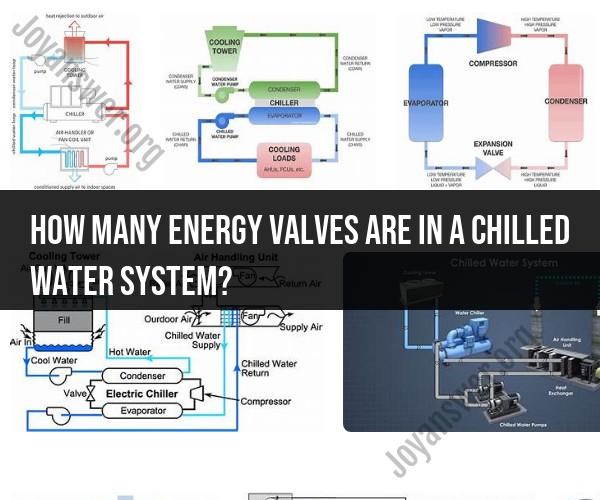

How many energy valves are in a chilled water system?

Energy valves, also known as control valves or modulating valves, play a critical role in chilled water systems. These valves are used to control the flow of chilled water through the system to maintain the desired temperature in various parts of a building or industrial facility. Here's an overview of their function and role:

Function:

Temperature Control: Energy valves are primarily used to control the temperature of chilled water in the system. By modulating the valve's position, the flow of chilled water is adjusted to maintain the setpoint temperature. This is essential for providing cooling to spaces and equipment.

Energy Efficiency: These valves help optimize the energy consumption of the chilled water system. By adjusting the flow as needed, energy valves ensure that the system doesn't overcool or undercool, which can result in energy savings.

Zoning: In larger buildings, multiple energy valves are often used to create different temperature zones. Each valve controls the flow of chilled water to a specific zone, allowing for individualized temperature control in different areas.

Balancing: Energy valves are used in system balancing to ensure an even distribution of chilled water throughout the system. This helps prevent temperature imbalances and ensures consistent cooling.

Role:

The role of energy valves in a chilled water system can vary depending on the system's complexity and design. In a typical chilled water system, you may find the following types of energy valves:

Chilled Water Supply Valve: This valve controls the flow of chilled water from the central chiller plant into the distribution system. It helps regulate the temperature of the chilled water entering the system.

Zone Control Valves: These valves are located at various points in the distribution system, often at or near the point where chilled water enters specific zones or spaces within a building. They modulate to control the flow of chilled water to individual areas, allowing for precise temperature control.

Secondary Circuit Valves: In some systems, secondary circuits may be used to further distribute chilled water within a zone or space. Energy valves in these circuits help control the flow of chilled water to specific cooling coils or equipment.

The number of energy valves in a chilled water system depends on the system's design, size, and complexity. Large commercial or industrial systems may have many energy valves, each serving a specific function and zone, while smaller systems may have fewer valves. The goal is to have the right number of valves to ensure effective temperature control, energy efficiency, and comfort throughout the building. The specific configuration of energy valves in a chilled water system is determined by the system's engineering and design.

Energy Valves in Chilled Water Systems: Understanding Their Role

Energy valves are a type of control valve that is designed to optimize the flow and energy consumption of chilled water systems. They work by measuring the temperature of the supply and return water, and then adjusting the flow rate accordingly to maintain a desired temperature difference, or delta-T.

Energy valves play an important role in chilled water systems by:

- Improving efficiency: By maintaining a high delta-T, energy valves can help to improve the efficiency of the chiller and the overall system. This is because a higher delta-T means that more heat is being removed from the water with each pass through the chiller, which reduces the amount of energy that the chiller needs to use.

- Reducing energy consumption: Energy valves can also help to reduce energy consumption by reducing the flow rate of chilled water when it is not needed. For example, if the building is not heavily occupied, the energy valve can reduce the flow of chilled water to the air handlers, which saves energy.

- Extending the life of the chiller: By maintaining a high delta-T, energy valves can help to extend the life of the chiller. This is because a higher delta-T reduces the amount of work that the chiller needs to do to cool the water, which reduces wear and tear on the compressor.

Managing Flow: The Significance of Energy Valves in Chilled Water Systems

The flow rate of chilled water is a critical factor in the performance of chilled water systems. Too much flow can lead to wasted energy, while too little flow can lead to inadequate cooling. Energy valves play a significant role in managing flow by accurately measuring and controlling the flow rate of chilled water.

Energy valves use a variety of technologies to measure flow, including ultrasonic flow meters, differential pressure sensors, and turbine flow meters. Once the flow rate has been measured, the energy valve can adjust the flow accordingly to maintain a desired delta-T or to meet the cooling needs of the building.

Efficiency and Control: Exploring Energy Valves in Chilled Water Systems

Energy valves can be used to improve the efficiency and control of chilled water systems in a variety of ways. For example, energy valves can be used to:

- Maintain a high delta-T: As mentioned above, maintaining a high delta-T is critical for improving the efficiency of the chiller and the overall system. Energy valves can be used to maintain a high delta-T by adjusting the flow rate of chilled water in response to changes in the load on the system.

- Reduce flow when not needed: Energy valves can also be used to reduce the flow of chilled water when it is not needed. This can be done by setting the energy valve to a lower flow rate during off-peak hours or when the building is not heavily occupied.

- Improve zone control: Energy valves can also be used to improve zone control in chilled water systems. This is done by using multiple energy valves to control the flow of chilled water to different zones in the building. This allows the cooling system to be optimized for the specific needs of each zone.

Overall, energy valves are a versatile and effective tool for improving the efficiency, control, and performance of chilled water systems. By accurately measuring and controlling the flow of chilled water, energy valves can help to reduce energy consumption, extend the life of the chiller, and improve the comfort of occupants.