How to calculate engine compression ratio and displacement?

Calculating engine compression ratio and displacement are important tasks in automotive engineering and maintenance. Both of these parameters provide valuable insights into an engine's performance and characteristics. Here's how to calculate each of them:

1. Engine Compression Ratio:

The compression ratio of an engine is a measure of how much the air-fuel mixture is compressed within the combustion chamber before ignition. It plays a crucial role in determining engine efficiency and power output. To calculate the compression ratio, you'll need two key values:

a. Cylinder Volume (V1): This is the volume of the cylinder when the piston is at bottom dead center (BDC). You can calculate it using the formula for the volume of a cylinder:

V1 = π × (bore/2)^2 × stroke

- Bore: The diameter of the cylinder (measured in meters or millimeters).

- Stroke: The length of the piston's travel inside the cylinder (measured in meters or millimeters).

b. Cylinder Combustion Chamber Volume (V2): This is the volume of the combustion chamber when the piston is at top dead center (TDC). You can typically find this value in the engine specifications or manufacturer's data.

Once you have these values, you can calculate the compression ratio (CR) using the following formula:

CR = (V1 + V2) / V2

The result is a dimensionless number representing the compression ratio. For example, if V1 is 500 cc and V2 is 50 cc, the compression ratio would be (500 + 50) / 50 = 11:1.

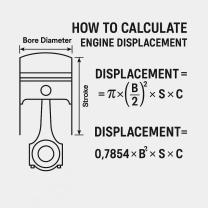

2. Engine Displacement:

Engine displacement, often referred to as "engine size," is a measure of the total volume of all the cylinders in an engine. It is typically expressed in cubic centimeters (cc) or liters (L). To calculate engine displacement, you need to know the following parameters:

a. Bore (B): The diameter of a single cylinder, usually measured in millimeters or centimeters.

b. Stroke (S): The length of the piston's travel inside a single cylinder, typically measured in millimeters or centimeters.

c. Number of Cylinders (N): The total number of cylinders in the engine.

Once you have these values, you can calculate engine displacement (D) using the following formula:

D = (π/4) × B^2 × S × N

- π is the mathematical constant pi (approximately 3.14159).

This formula calculates the displacement of one cylinder, so to find the total engine displacement, you multiply this value by the number of cylinders (N). The result will be in cubic centimeters (cc) or liters (L), depending on the units used for B, S, and N.

For example, if you have an engine with a bore of 80 mm, a stroke of 90 mm, and 4 cylinders, you can calculate its displacement as:

D = (π/4) × (80 mm)^2 × 90 mm × 4D ≈ 2304 cc or 2.3 liters

So, the engine displacement is approximately 2.3 liters.

These calculations are fundamental for understanding an engine's performance and specifications. Keep in mind that engine designs and configurations can vary, so it's essential to use accurate measurements and consult the manufacturer's specifications when available for precise calculations.

Engine Compression Ratio Calculation Methods

There are two main methods for calculating engine compression ratio:

- Geometric compression ratio: This is the simplest method and is calculated by dividing the total cylinder volume by the clearance volume. The clearance volume is the volume of the combustion chamber when the piston is at top dead center (TDC).

- Effective compression ratio: This is a more accurate method that takes into account the effects of factors such as valve timing, piston ring sealing, and combustion chamber shape. To calculate the effective compression ratio, you need to use a computer simulation or a complex mathematical formula.

How to Determine Engine Displacement

Engine displacement is the total volume of all the cylinders in an engine. It is typically measured in cubic inches (ci) or cubic centimeters (cc). To determine engine displacement, you need to know the bore and stroke of the engine.

The bore is the diameter of the cylinder and the stroke is the distance the piston travels from TDC to bottom dead center (BDC). The formula for calculating engine displacement is as follows:

Engine displacement = (bore^2 x pi x stroke) x number of cylinders

For example, a 4-cylinder engine with a bore of 3.5 inches and a stroke of 3.8 inches has a displacement of 90.8 cubic inches.

Calculating Engine Compression Ratio and Its Significance

Once you know the engine displacement and clearance volume, you can calculate the engine compression ratio using the following formula:

Engine compression ratio = (total cylinder volume) / (clearance volume)

For example, a 4-cylinder engine with a displacement of 90.8 cubic inches and a clearance volume of 58 cubic inches has a compression ratio of 10:1.

The engine compression ratio is important because it affects the performance and efficiency of the engine. A higher compression ratio allows for more complete combustion of the fuel-air mixture, which results in more power and better fuel economy. However, a higher compression ratio also requires higher octane fuel to prevent pre-ignition.

Here are some of the benefits of having a higher engine compression ratio:

- Increased power

- Improved fuel economy

- Reduced emissions

- Better acceleration

- Higher top speed

However, it is important to note that there are also some drawbacks to having a higher engine compression ratio:

- Requires higher octane fuel

- More prone to detonation

- Can be more expensive to build and maintain

The optimal engine compression ratio depends on a number of factors, such as the type of fuel used, the design of the engine, and the desired performance characteristics.