How to calculate construction cost?

Calculating construction costs involves estimating the expenses associated with materials, labor, equipment, and other factors involved in a construction project. Here's a guide on how to calculate construction costs:

1. Scope Definition:

- Clearly define the scope of the construction project. Identify the specific tasks, materials, and labor required for each aspect of the project.

2. Quantity Takeoff:

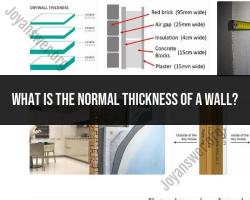

- Perform a quantity takeoff to determine the quantity of materials needed for each component of the project. This includes materials like concrete, steel, lumber, etc.

3. Material Costs:

- Obtain current prices for all required materials. Prices may vary based on location, suppliers, and market conditions. Consider delivery charges and taxes when calculating material costs.

4. Labor Costs:

- Estimate the labor hours required for each task and apply the appropriate labor rates. Labor rates should include wages, benefits, and other associated costs.

5. Equipment Costs:

- If specialized equipment is needed for the project, factor in the costs of renting or owning the equipment. Consider fuel, maintenance, and operator costs.

6. Subcontractor Costs:

- If subcontractors will be involved in the project, obtain quotes or estimates from them for their specific scope of work.

7. Overhead and Indirect Costs:

- Include overhead costs, such as administrative expenses, insurance, permits, and other indirect costs associated with the project.

8. Contingency Allowance:

- Add a contingency allowance to account for unforeseen circumstances or changes in the project. Contingencies are typically expressed as a percentage of the total project cost.

9. Profit Margin:

- Include a profit margin in the cost estimate. This is the amount that the contractor or builder expects to make as a profit on the project. Profit margins are typically expressed as a percentage of the total project cost.

10. Calculate Total Construction Cost:

- Sum up all the estimated costs, including materials, labor, equipment, subcontractor costs, overhead, contingency, and profit margin. The total represents the estimated construction cost.

Example Calculation:

Let's say you're estimating the cost of constructing a new office building. Your estimated costs might look like this:

- Material Costs: $500,000

- Labor Costs: $700,000

- Equipment Costs: $50,000

- Subcontractor Costs: $200,000

- Overhead and Indirect Costs: $100,000

- Contingency (5%): $75,000

- Profit Margin (10%): $150,000

Total Construction Cost = $500,000 + $700,000 + $50,000 + $200,000 + $100,000 + $75,000 + $150,000 = $1,775,000

Tips:

Use Software Tools:

- Construction estimating software tools can help streamline the process and provide accurate calculations.

Stay Informed on Market Prices:

- Regularly update material and labor costs based on current market prices to ensure accuracy.

Consult with Experts:

- Seek input from experienced contractors, estimators, or industry professionals to validate your estimates.

Review and Revise:

- Periodically review and revise cost estimates as the project progresses and new information becomes available.

Keep in mind that construction costs can vary based on project complexity, location, market conditions, and other factors. Regularly reviewing and updating estimates is crucial for maintaining accuracy throughout the project.

What methods are employed to calculate the costs involved in construction projects?

Several methods are employed to calculate the costs involved in construction projects, each with its own strengths and weaknesses. Here are some of the most common methods:

1. Bottom-Up Estimating:

This method involves breaking down the project into individual components (e.g., materials, labor, equipment) and estimating the cost of each component individually. The individual costs are then summed up to arrive at the total project cost.

Advantages:

- Highly accurate for detailed projects

- Provides detailed cost breakdown

- Identifies potential cost overruns early on

Disadvantages:

- Time-consuming and labor-intensive

- Requires detailed project information

- Susceptible to errors in individual component estimates

2. Parametric Estimating:

This method uses historical data and cost parameters to estimate the cost of similar projects. The parameters can include factors such as project size, complexity, location, and construction type.

Advantages:

- Quick and efficient

- Useful for preliminary estimates

- Requires less detailed project information

Disadvantages:

- Less accurate than bottom-up estimating

- May not be suitable for unique or complex projects

- Can be biased based on the quality of historical data

3. Unit Price Estimating:

This method involves assigning a unit price to each unit of work (e.g., square footage, linear foot) based on historical data or industry standards. The total cost is then calculated by multiplying the unit price by the quantity of work.

Advantages:

- Simple and straightforward

- Useful for repetitive tasks

- Useful for estimating costs early in the design process

Disadvantages:

- May not be accurate for complex or unique projects

- Requires accurate unit prices

- Can be susceptible to changes in scope

4. Assembly Cost Estimating:

This method estimates the cost of assembling prefabricated components into a finished product. The cost of each component is added to the assembly costs to arrive at the total project cost.

Advantages:

- Efficient for projects using prefabricated components

- Reduces construction time and costs

- Provides greater cost certainty

Disadvantages:

- Requires detailed information about prefabricated components

- May not be suitable for all projects

- Limited flexibility for design changes

5. 3-Point Estimating:

This method involves estimating three possible cost outcomes for the project: optimistic, pessimistic, and most likely. These estimates are then used to calculate a range of possible project costs.

Advantages:

- Accounts for uncertainty in project costs

- Provides a range of possible outcomes

- Useful for risk management

Disadvantages:

- Requires expert judgment to estimate three cost points

- Can be time-consuming

- May not be as accurate as other methods

Choosing the right method depends on several factors, including the project size, complexity, stage of development, and available information. In many cases, a combination of different methods may be used to achieve a more accurate and reliable estimate.

Here are some additional resources that you may find helpful:

- Construction Cost Estimating: A Practical Guide by John D. Schaufelberger

- Cost Engineering Handbook by Richard L. Tucker and Jack R. Holland

- American Society of Professional Estimators (ASPE) https://aspe.org/: https://aspe.org/