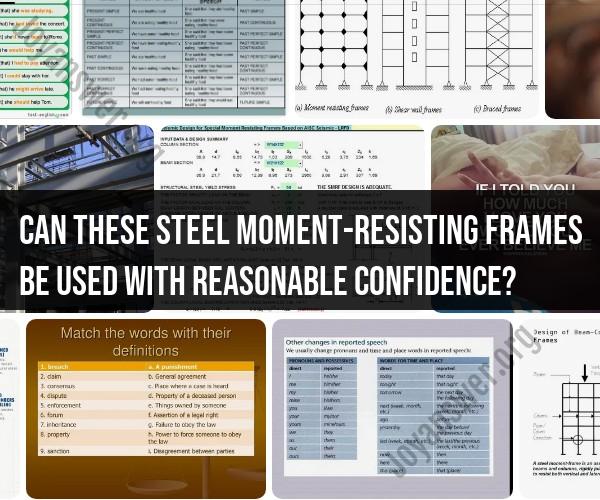

Can these steel moment-resisting frames be used with reasonable confidence?

Steel moment-resisting frames are a common and reliable structural system used in building construction to resist lateral forces, such as those generated by wind or seismic events. When designed and constructed properly, these frames can be used with a high degree of confidence to provide structural stability and safety. Here are some key points about steel moment-resisting frames and their practical usage:

Engineering Design: Steel moment-resisting frames are typically designed by structural engineers who follow established engineering codes and standards. In the United States, for example, the American Institute of Steel Construction (AISC) provides guidelines for designing steel structures. The use of these standards helps ensure that frames are designed to meet safety and performance requirements.

Seismic Resistance: Steel moment frames are often employed in earthquake-prone regions because of their excellent seismic resistance. Special detailing and design considerations are incorporated to enhance their ability to absorb and dissipate seismic energy. These frames are designed to provide life safety and limit structural damage during an earthquake.

Quality Materials and Construction: The use of high-quality steel materials and proper construction techniques is crucial to the performance of these frames. Welding, bolting, and connection details must meet specific standards to ensure the integrity of the frame.

Inspection and Quality Control: During construction, inspections and quality control measures are essential to verify that the frame is being built in accordance with the approved design and specifications. Quality control helps identify and rectify any issues early in the construction process.

Load Testing: In some cases, load testing may be conducted to ensure that the frame can withstand its intended loads and forces. Load testing provides additional confidence in the structural system's performance.

Experienced Professionals: The design and construction of steel moment-resisting frames should involve experienced and qualified professionals, including structural engineers and steel fabricators.

Regulatory Compliance: Compliance with local building codes and regulations is critical. Building authorities review and approve the structural design and construction plans to ensure they meet safety requirements.

Periodic Inspection and Maintenance: After construction, it's important to conduct regular inspections and maintenance to ensure the ongoing performance and safety of the frame. This includes checking for signs of corrosion or damage.

Documentation and Record-Keeping: Maintain comprehensive documentation of the frame's design, construction, and inspection. This information can be valuable for future assessments and renovations.

In summary, steel moment-resisting frames are a well-established and reliable structural system used in building construction. When used in accordance with engineering standards, designed by qualified professionals, and constructed with attention to detail and quality, they can be used with a high degree of confidence. However, it's essential to follow best practices, adhere to regulations, and prioritize safety throughout the design, construction, and maintenance processes.

Assessing the Use of Steel Moment-Resisting Frames

Steel moment-resisting frames (SMRFs) are a type of structural system that is commonly used in tall buildings and other structures that require high strength and stiffness. SMRFs are well-suited for resisting lateral loads, such as those caused by wind and earthquakes.

Considerations for Steel Moment-Resisting Frame Design

There are a number of factors that must be considered when designing an SMRF. These factors include:

- The type of structure: The type of structure will determine the design loads that the SMRF must be able to resist.

- The height and configuration of the structure: The height and configuration of the structure will affect the distribution of lateral loads and the design of the SMRF.

- The materials used: SMRFs are typically made of structural steel, but other materials, such as reinforced concrete, can also be used.

- The connections between members: The connections between members are critical to the performance of an SMRF. Connections must be designed to be strong and stiff enough to resist the design loads.

Factors Influencing the Confidence in Frame Use

SMRFs are a well-established and proven structural system. There is a large body of research and experience that supports the use of SMRFs in a variety of applications.

Some of the factors that contribute to the confidence in the use of SMRFs include:

- Their ability to resist lateral loads: SMRFs have a long history of successful performance in resisting lateral loads, such as those caused by wind and earthquakes.

- Their ductility: SMRFs are ductile, meaning that they can undergo significant deformation without failure. This ductility is important for absorbing the energy of a seismic event.

- Their reparability: SMRFs are typically repairable after a seismic event. This means that they can be restored to their original condition, or close to it, with the necessary repairs.

Structural Engineering and Safety Evaluations

Structural engineers play a critical role in the design and safety assessment of SMRFs. Structural engineers must have a thorough understanding of the behavior of SMRFs under lateral loads in order to design them safely.

Structural engineers also perform safety evaluations of existing SMRFs to assess their condition and to identify any potential weaknesses. This information can be used to develop retrofit plans to improve the seismic performance of existing SMRFs.

Standards and Regulations for Steel Moment Frames

There are a number of standards and regulations that apply to the design and construction of SMRFs. These standards and regulations are intended to ensure that SMRFs are designed and constructed safely.

Some of the most common standards and regulations that apply to SMRFs include:

- American Institute of Steel Construction (AISC) 358-16, Standard for Seismic Design of Steel Structures: This standard provides comprehensive guidance on the design of SMRFs.

- International Building Code (IBC): The IBC is a model building code that is adopted by many jurisdictions in the United States. The IBC contains requirements for the design and construction of SMRFs.

- ASCE/SEI 7-16, Minimum Design Loads and Associated Criteria for Buildings and Other Structures: This standard provides minimum design loads for buildings and other structures, including SMRFs.

SMRFs are a reliable and well-proven structural system for resisting lateral loads. Structural engineers play a critical role in the design and safety assessment of SMRFs. Standards and regulations are in place to ensure that SMRFs are designed and constructed safely.