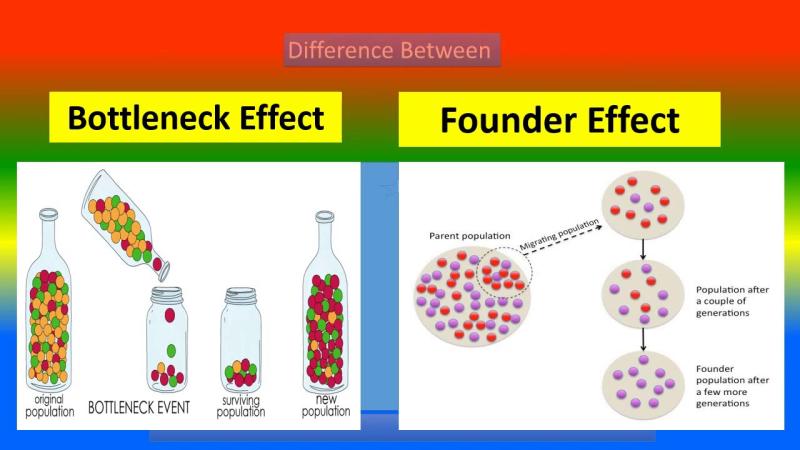

What is the difference between bottleneck and non-bottleneck?

In the context of resource allocation and process optimization, the terms "bottleneck" and "non-bottleneck" refer to the capacity and utilization of resources within a system.

Bottleneck

A bottleneck is a resource in a system that is operating at its maximum capacity or beyond, causing a restriction in the overall flow of work or output of the system. It is the limiting factor that prevents the system from achieving its full potential throughput.

Non-Bottleneck

A non-bottleneck is a resource in a system that has excess capacity relative to the demand placed upon it. It is not operating at its maximum capacity, and there is room for increased utilization without causing a bottleneck.

Key Differences

Capacity Utilization: Bottlenecks are fully utilized, while non-bottlenecks have excess capacity.

Impact on Throughput: Bottlenecks limit the overall throughput of the system, while non-bottlenecks do not.

Focus of Improvement: Bottlenecks are a priority for improvement efforts, as increasing their capacity can significantly enhance overall throughput. Non-bottlenecks may not require immediate attention.

Real-World Examples

Production Line: In a manufacturing assembly line, a machine that is consistently performing slower than the others creates a bottleneck, slowing down the entire production process.

Traffic Flow: A narrow section of a road with a single lane acts as a bottleneck during peak traffic hours, restricting the flow of vehicles and causing congestion.

Customer Service: In a call center, a limited number of available customer service representatives can create a bottleneck during periods of high call volume, leading to longer wait times for customers.

Identifying and Addressing Bottlenecks

Analyze Resource Utilization: Monitor the utilization of various resources in the system to identify potential bottlenecks.

Evaluate Workflows: Examine the flow of work through the system to identify points of congestion or delays.

Prioritize Improvement Efforts: Focus on addressing the most critical bottlenecks that have the greatest impact on overall throughput.

Implement Solutions: Implement appropriate solutions to increase the capacity of bottlenecks, such as adding resources, upgrading equipment, or optimizing processes.

Continuous Monitoring: Continuously monitor resource utilization and system performance to identify new bottlenecks and maintain efficient operation.

By understanding the distinction between bottlenecks and non-bottlenecks, organizations can effectively allocate resources, optimize processes, and maximize their overall productivity.

Exploring the Concept of Bottlenecks in Different Contexts:This article delves into the concept of bottlenecks, which refer to points of congestion or restriction in various contexts. It explores how bottlenecks manifest in different domains, from traffic to manufacturing, and the common characteristics they share.

What distinguishes a bottleneck from a non-bottleneck in various domains:Bottlenecks are typically characterized by their limited capacity, causing delays or constraints in the flow of processes. In contrast, non-bottlenecks do not impede the overall flow significantly and often have sufficient capacity to handle tasks efficiently.

How can identifying bottlenecks improve efficiency in project management:Identifying and addressing bottlenecks in project management is vital for enhancing efficiency. By recognizing and resolving these points of constraint, project managers can optimize resource allocation, streamline workflow, reduce delays, and ensure projects stay on track.

Examples of Bottleneck Analysis in Manufacturing Processes:In manufacturing, bottleneck analysis can be exemplified by scenarios where a particular machine or workstation operates at a slower rate than others, causing a backlog in production. By identifying and addressing these bottlenecks, manufacturers can increase production efficiency and reduce lead times.

Strategies for Addressing and Mitigating Bottlenecks in Business Operations:To address and mitigate bottlenecks in business operations, organizations can employ strategies such as process optimization, resource reallocation, technology upgrades, and workforce training. These efforts are aimed at reducing congestion points and improving overall operational efficiency.