What is the tolerance for deviation from specified panel thickness?

The tolerance for deviation from the specified panel thickness in manufacturing can vary depending on several factors, including the type of material being used, the manufacturing process, industry standards, and the specific requirements of the project. There isn't a single universal tolerance that applies to all situations. Here are some key considerations:

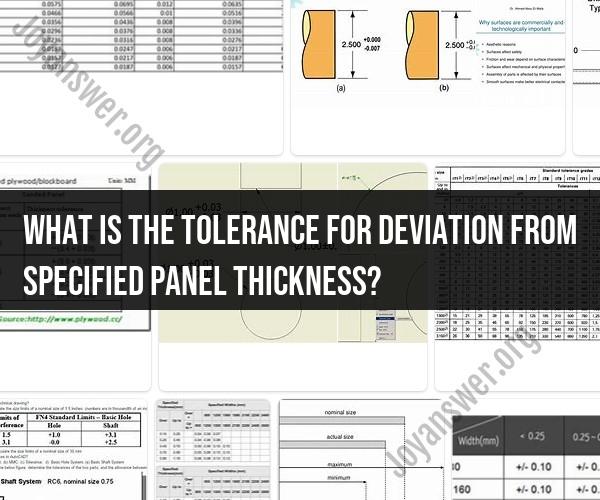

Industry Standards: Many industries have established standards and guidelines that specify tolerances for various manufacturing processes, including the thickness of panels. These standards are often developed by organizations such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). You should consult the relevant industry standards for specific tolerance requirements.

Material Type: The type of material being used can impact the allowable tolerance. For example, sheet metal panels may have different tolerance requirements compared to wood or plastic panels.

Manufacturing Process: The manufacturing method employed also influences tolerances. Precision machining processes typically have tighter tolerances compared to casting or molding processes.

Project Requirements: The specific requirements of the project or product being manufactured play a significant role in determining acceptable tolerances. Some projects may require extremely tight tolerances for precise fit and function, while others may allow for more significant variations.

Quality Control: Effective quality control measures are essential to ensure that panels meet the specified thickness requirements. Quality control processes may involve regular measurements, inspections, and adjustments during production.

Customer Preferences: In some cases, the customer's preferences or contractual agreements may dictate the allowable tolerances for panel thickness.

Cost Considerations: Tighter tolerances often require more precise manufacturing processes, which can increase production costs. Therefore, there may be a trade-off between achieving extremely tight tolerances and cost-effectiveness.

To determine the specific tolerance for deviation from specified panel thickness in a manufacturing project, you should consult the engineering drawings, project specifications, and industry standards that apply to your situation. These documents should provide clear guidance on acceptable tolerances and quality control procedures.

It's essential to communicate and coordinate with the design and engineering teams, as well as any relevant industry experts, to ensure that the specified tolerances are achievable and appropriate for the intended application.