What is a pellet die?

A pellet die, also known as a pellet mill die or pelletizing die, is a crucial component in the process of pelletizing. Pelletizing is a manufacturing process used primarily in the agriculture and biomass industries to create small, compacted pellets from various raw materials. These pellets are often used for purposes such as animal feed, fuel, and more. The pellet die plays a central role in shaping and forming the pellets.

Here's an explanation of the purpose and function of a pellet die:

Purpose of a Pellet Die:The primary purpose of a pellet die is to shape and compress raw materials into uniform, dense, and cylindrical pellets. Pellets are commonly used in various industries, including:

Animal Feed: Pellet dies are used to create high-quality animal feed pellets, ensuring that animals receive consistent nutrition.

Biomass Fuel: In the biomass industry, pellet dies are used to manufacture wood pellets, crop residues, and other organic materials into an efficient and clean-burning fuel source.

Biomass Pellets: Beyond fuel, biomass pellet dies are employed to create biomass pellets used in applications such as renewable energy generation, as well as in heating systems.

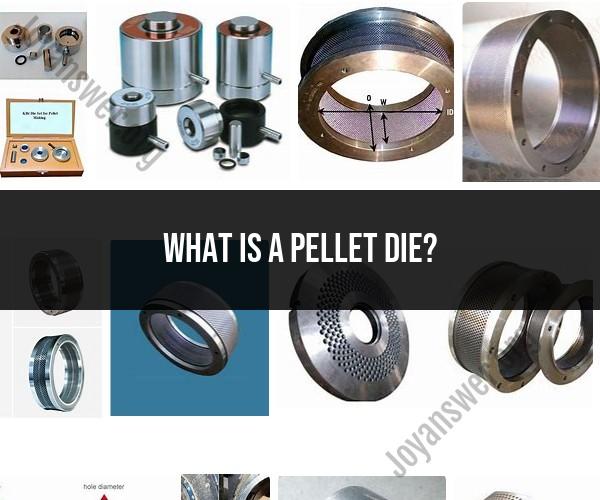

Function of a Pellet Die:A pellet die is a cylindrical or ring-shaped device with small perforations or holes through which raw materials are forced to create pellets. Its functions include:

Compression: The pellet die compresses and compacts the raw materials as they pass through the perforations. This compression process binds the particles together, forming solid pellets.

Shaping: The shape and size of the perforations in the die determine the shape and size of the resulting pellets. Dies can have various hole diameters and patterns to create different pellet sizes and shapes.

Consistency: A well-designed pellet die ensures that the resulting pellets are uniform in size, density, and composition. This consistency is vital, especially in industries like animal feed, where precise nutrition delivery is critical.

Heat Generation: The compression process generates heat due to the friction between the raw materials and the die. This heat can help soften certain materials, making them more malleable and easier to pelletize.

Cooling: In some pelletizing processes, cooling mechanisms are integrated to prevent overheating and maintain the structural integrity of the pellets.

Durable Construction: Pellet dies are typically made of durable materials like high-quality alloy steel to withstand the high pressures and wear associated with the pelletization process.

Overall, the pellet die serves as the central component in transforming loose raw materials into compacted pellets suitable for a wide range of applications. The design and specifications of the die, as well as the pelletizing machinery used, can be customized to meet the specific requirements of different industries and applications.

Pellet Dies in Manufacturing: Exploring Their Role in Pellet Production

Pellet dies are a critical component of pellet manufacturing. They are used to shape and compress raw materials into pellets. Pellet dies are typically made of high-strength steel or alloy materials and are designed to withstand the high temperatures and pressures of the pelletizing process.

There are two main types of pellet dies: ring dies and flat dies. Ring dies are more common and are used to produce high volumes of pellets. Flat dies are typically used for smaller production runs or for specialized applications.

The role of pellet dies in pellet production is to:

- Shape the raw material into pellets of the desired size and shape

- Compress the raw material to increase its density and durability

- Create a smooth surface on the pellets to reduce friction and wear

The Heart of Pellet Manufacturing: Understanding the Pellet Die

The pellet die is the heart of the pellet mill. It is responsible for shaping and compressing the raw material into pellets. The pellet die has a series of holes that are drilled to the desired size and shape of the pellets.

The raw material is fed into the pellet mill and is compressed by the rollers against the pellet die. This forces the raw material through the holes in the pellet die, forming pellets. The pellets are then ejected from the pellet mill and can be collected for further processing or use.

Molded by Design: The Importance of the Pellet Die in Production

The pellet die is an important factor in the quality and efficiency of pellet production. A well-designed pellet die can help to produce pellets that are consistent in size, shape, and density. It can also help to reduce wear and tear on the pellet mill.

Some of the factors to consider when choosing a pellet die include:

- The type of raw material being pelletized

- The desired size, shape, and density of the pellets

- The capacity of the pellet mill

- The budget

A reputable pellet die manufacturer can help you to choose the right pellet die for your needs.

Here are some tips for using pellet dies effectively:

- Keep the pellet die clean and free of debris.

- Inspect the pellet die regularly for signs of wear and tear.

- Use the correct lubricant for the pellet die.

- Do not overload the pellet mill.

- Replace the pellet die when necessary.

By following these tips, you can help to ensure that your pellet die produces high-quality pellets for many years to come.