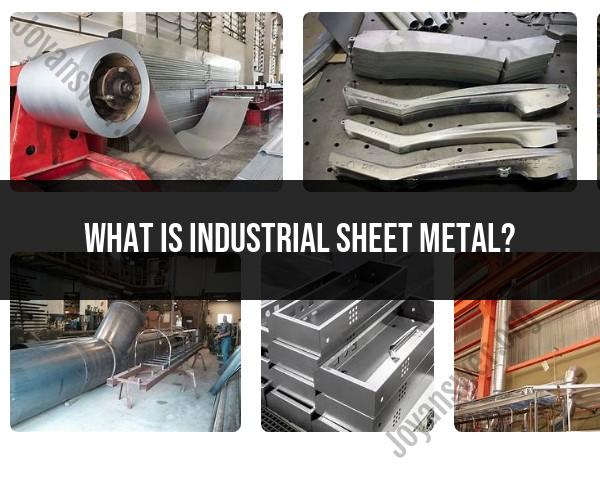

What is industrial sheet metal?

Industrial sheet metal refers to thin, flat pieces of metal that are used in various industrial applications. These metal sheets are typically formed through processes like rolling, stamping, or extrusion to achieve the desired thickness and shape. The characteristics and applications of industrial sheet metal make it a versatile material in manufacturing and construction industries. Here are key aspects of industrial sheet metal:

Characteristics of Industrial Sheet Metal:

Material Types:

- Industrial sheet metal can be made from a variety of materials, including steel, aluminum, stainless steel, brass, copper, and other alloys. The choice of material depends on the specific requirements of the application, considering factors such as strength, corrosion resistance, and cost.

Thickness:

- Sheet metal is characterized by its thinness. The thickness can vary significantly, ranging from extremely thin foils to thicker sheets. The gauge system is commonly used to specify sheet metal thickness, with lower gauge numbers representing thicker sheets.

Formability:

- Sheet metal is known for its high formability, meaning it can be easily bent, cut, stamped, or rolled into various shapes without breaking or cracking. This characteristic makes it suitable for a wide range of manufacturing processes.

Strength and Durability:

- Depending on the chosen material, industrial sheet metal can offer high strength and durability. This makes it suitable for applications requiring structural integrity, such as in the construction of buildings, vehicles, and machinery.

Surface Finish:

- Sheet metal surfaces can be finished in different ways, including polished, painted, coated, or left untreated. Surface finish is often chosen based on aesthetic preferences, corrosion resistance, and the intended application.

Corrosion Resistance:

- Some sheet metal materials, such as stainless steel and aluminum, exhibit excellent corrosion resistance. This property is crucial in applications where the material is exposed to harsh environmental conditions.

Conductivity:

- Metals like copper and aluminum are known for their high electrical conductivity. Sheet metal made from these materials is commonly used in electrical and electronic applications.

Applications of Industrial Sheet Metal:

Construction and Architecture:

- Industrial sheet metal is widely used in the construction industry for roofing, cladding, and structural components. It offers durability and versatility in creating complex architectural shapes.

Automotive Manufacturing:

- Sheet metal is a fundamental material in the automotive industry. It is used for body panels, chassis components, and other structural elements in vehicles.

Aerospace Industry:

- In aerospace manufacturing, sheet metal is employed to create lightweight but strong components for aircraft and spacecraft. The formability and strength of sheet metal make it valuable in this industry.

Appliance Manufacturing:

- Household appliances, such as refrigerators, ovens, and washing machines, often incorporate sheet metal components due to their strength, formability, and resistance to corrosion.

HVAC Systems:

- Sheet metal is commonly used in the fabrication of heating, ventilation, and air conditioning (HVAC) systems. Ductwork and other components are often made from sheet metal due to its ductility and ease of forming.

Metal Furniture and Fixtures:

- Sheet metal is used in the manufacturing of furniture, lighting fixtures, cabinets, and various decorative items due to its malleability and the ability to achieve intricate designs.

Electronics and Electrical Panels:

- Copper and aluminum sheet metals are used in the production of electrical panels, enclosures, and electronic components due to their electrical conductivity and formability.

Containers and Packaging:

- Sheet metal is employed in the fabrication of containers, packaging materials, and enclosures for various products, providing a combination of strength and protection.

Energy Industry:

- Sheet metal is used in the energy sector for applications such as manufacturing components for renewable energy systems, power distribution, and oil and gas infrastructure.

Medical Equipment:

- Certain medical devices and equipment are manufactured using sheet metal due to its hygienic properties, ease of sterilization, and the ability to meet stringent design requirements.

Industrial sheet metal plays a vital role in modern manufacturing, offering a balance of strength, formability, and versatility. The specific characteristics and applications vary depending on the type of metal used and the requirements of the industry or application in question.

Industrial Sheet Metal: Shaping the World Around Us

Industrial sheet metal is a broad term encompassing various thin metal sheets used in a wide range of manufacturing applications. It forms the backbone of countless everyday products, from cars and appliances to machinery and building materials. Let's delve into its versatility and importance:

1. Definition and Role in Manufacturing:

- Definition: Industrial sheet metal refers to metal sheets with thicknesses typically ranging from 0.006 inches to 0.25 inches, made from different metals like steel, aluminum, copper, and stainless steel. These sheets are readily available in various sizes, shapes, and finishes.

- Role in Manufacturing: Industrial sheet metal is a highly versatile material, offering numerous advantages like:

- Formability: It can be bent, cut, stamped, and welded into different shapes and forms with relative ease.

- Strength and durability: Depending on the metal used, it offers diverse strength properties for various applications.

- Corrosion resistance: Certain metals like stainless steel provide excellent resistance to corrosion, making them ideal for specific uses.

- Conductivity: Some metals like copper excel in electrical and thermal conductivity, making them suitable for specific components.

2. Applications and Industries:

Industrial sheet metal finds application in a vast array of industries and products, including:

- Transportation: Automobile bodies, truck beds, aircraft parts, ship hulls.- Construction: Roofing panels, wall cladding, ductwork, piping.- Appliances: Washing machine and dryer drums, oven panels, refrigerator shelves.- Electronics: Computer casings, heat sinks, circuit board components.- Machinery: Industrial equipment casings, gears, blades, enclosures.- Medical Devices: Prosthetics, surgical instruments, sterilization trays.- Furniture and household goods: Kitchenware, storage containers, shelving units.

3. Contribution to Production:

Industrial sheet metal contributes significantly to the production of various goods in several ways:

- Cost-effectiveness: Compared to other materials, sheet metal offers efficient use of material and minimizes waste, making it a cost-effective choice.- Design flexibility: Its formability allows for diverse design possibilities, enabling manufacturers to create complex shapes and functions.- Lightweight properties: Certain metals like aluminum offer strength while being lightweight, ideal for applications requiring weight reduction.- Mass production: Sheet metal readily integrates with automated manufacturing processes, facilitating efficient and rapid production of large quantities of goods.

Overall, industrial sheet metal is a fundamental material in modern manufacturing, playing a crucial role in shaping countless products around us. Its versatility, strength, and ease of use make it a vital component of diverse industries, contributing to efficient production and innovative design solutions.