How do you get OSHA compliant?

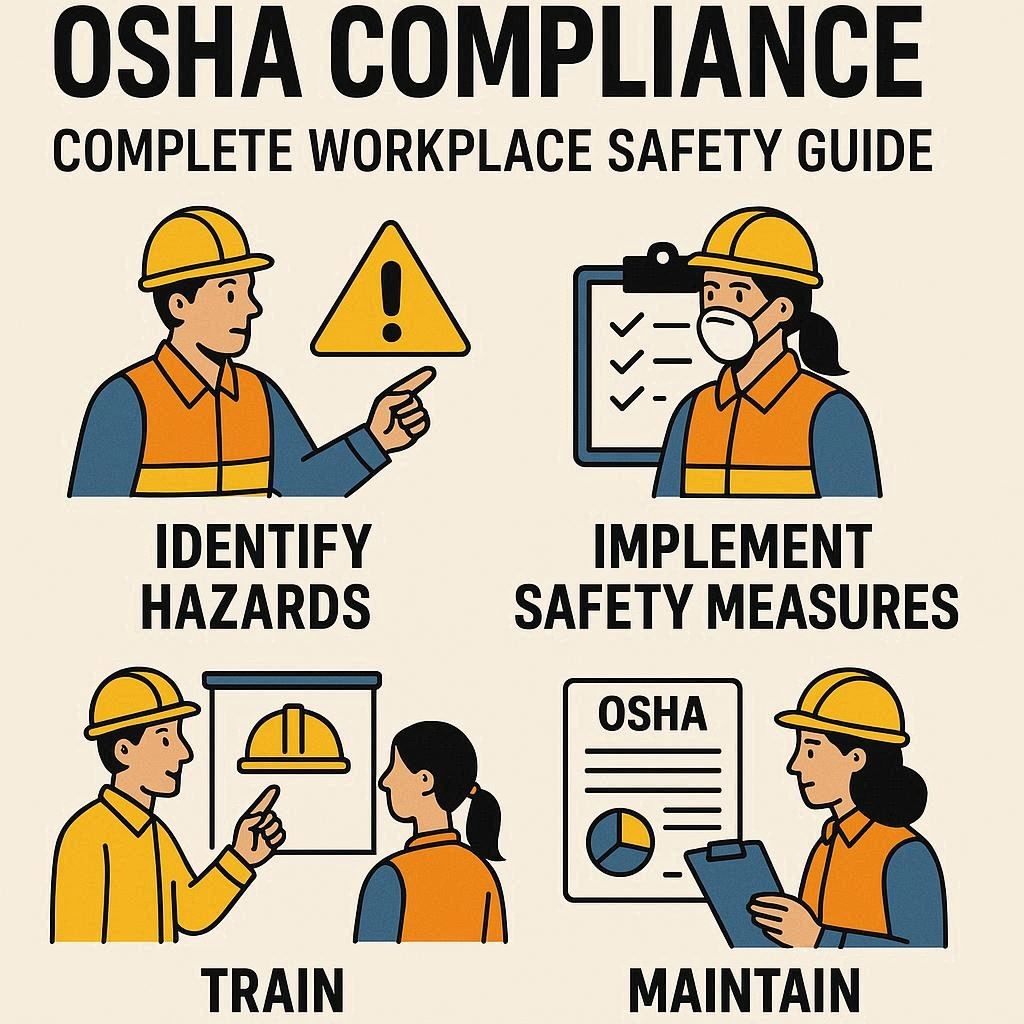

Here’s a clear, step-by-step guide to achieving OSHA compliance in your workplace:

1. Understand OSHA Requirements

Know the standards: OSHA (Occupational Safety and Health Administration) sets standards for workplace safety and health in the U.S. These include regulations for:

Hazard communication

Machine safety

Fall protection

Electrical safety

Personal protective equipment (PPE)

Recordkeeping and reporting

Industry-specific rules: OSHA has additional rules depending on the industry, e.g., construction, healthcare, manufacturing.

2. Conduct a Workplace Safety Assessment

Inspect hazards: Identify physical, chemical, biological, and ergonomic risks.

Review past incidents: Look at injury logs, near-misses, and OSHA 300/301 logs.

Evaluate current safety programs: Check if existing policies meet OSHA standards.

3. Develop a Written Safety Program

Include:

Safety policies and procedures

Emergency action plans

Hazard communication programs

PPE guidelines

Training schedules

4. Provide OSHA Training

Mandatory training: Employees must be trained in:

General safety practices

Hazard-specific protocols

Emergency response

Keep records: Document all training sessions and participants.

5. Maintain Safety Equipment and PPE

Ensure all equipment is:

Regularly inspected and maintained

Properly labeled and in working order

Provide PPE such as helmets, gloves, goggles, or respirators as required.

6. Implement Hazard Communication

Chemical labeling: Follow OSHA’s Hazard Communication Standard (HCS) for chemicals.

Safety Data Sheets (SDS): Maintain up-to-date SDS for all hazardous substances.

Employee access: Ensure employees know where to find SDS and labels.

7. Recordkeeping and Reporting

Injury logs: Maintain OSHA 300 logs for work-related injuries and illnesses.

Reporting serious incidents: Fatalities or hospitalizations must be reported within OSHA-required timeframes.

Periodic review: Regularly analyze incidents to prevent recurrence.

8. Conduct Regular Inspections and Audits

Routine workplace inspections help ensure ongoing compliance.

Correct hazards promptly and document actions taken.

9. Engage Employees in Safety

Encourage reporting of unsafe conditions.

Form safety committees.

Reward proactive safety behavior.

10. Stay Updated

OSHA regulations can change.

Subscribe to OSHA updates or consult industry associations.

Summary:

To get OSHA compliant, you must understand the rules, identify hazards, train employees, maintain equipment, implement proper documentation, and continuously monitor your workplace for safety. Compliance is an ongoing process, not a one-time effort.

Here’s a visual checklist for OSHA compliance that you can use as a quick reference at your workplace:

OSHA Compliance Checklist

1. Understand OSHA Requirements

Review general and industry-specific OSHA standards

Identify applicable safety regulations

2. Conduct Workplace Safety Assessment

Inspect for physical, chemical, biological, and ergonomic hazards

Analyze past incidents and near-misses

Evaluate existing safety programs

3. Develop Written Safety Programs

Safety policies and procedures

Emergency action plans

Hazard communication program

PPE guidelines

Training schedules

4. Provide Employee Training

General safety practices

Hazard-specific protocols

Emergency response procedures

Document all training sessions

5. Maintain Equipment and PPE

Inspect and maintain equipment regularly

Ensure PPE is available, in good condition, and used correctly

6. Implement Hazard Communication

Label chemicals properly

Maintain up-to-date Safety Data Sheets (SDS)

Ensure employees can access SDS and labels

7. Recordkeeping and Reporting

Maintain OSHA 300 logs

Report fatalities or hospitalizations promptly

Analyze incidents to prevent recurrence

8. Conduct Regular Inspections & Audits

Schedule routine workplace inspections

Correct hazards immediately

Document actions taken

9. Engage Employees in Safety

Encourage hazard reporting

Form safety committees

Reward proactive safety behavior

10. Stay Updated

Follow OSHA updates and guidance

Adjust safety programs as regulations change

1. The Key Steps to Becoming OSHA Compliant in the Workplace

Becoming compliant with the Occupational Safety and Health Administration (OSHA) is a continuous process that involves identifying and controlling hazards in your workplace.

Establish a safety and health program: This is the foundation of compliance.

An effective program includes strong management leadership, worker participation, and a system for finding and fixing hazards. Identify hazards: Regularly inspect your workplace to find potential dangers.

This includes looking for things like fall hazards, improper electrical wiring, chemical exposures, and unsafe equipment. Implement controls: Once hazards are identified, you must take steps to control or eliminate them. OSHA recommends a hierarchy of controls, starting with the most effective: elimination (physically removing the hazard), substitution (replacing the hazard), engineering controls (isolating people from the hazard), administrative controls (changing the way people work), and finally, personal protective equipment (PPE).

Train employees: Workers must be trained on the hazards they may encounter and how to use safety equipment and procedures.

This training must be in a language and vocabulary they can understand. Display the OSHA poster: Employers are required to prominently display the "Job Safety and Health: It's the Law" poster, which informs employees of their rights under the OSH Act.

2. How to Create an Effective Safety and Health Program to Meet OSHA Standards

An effective safety and health program is a proactive approach to preventing injuries and illnesses.

Management Leadership: Management must show a commitment to safety, leading by example and making safety a core value of the company culture.

Worker Participation: Workers are on the front lines and often have the best insight into workplace hazards.

An effective program encourages workers to participate in safety committees, report hazards without fear of retaliation, and provide input on safety procedures. Hazard Identification and Assessment: This involves a systematic process of identifying and evaluating all potential hazards in the workplace.

Hazard Prevention and Control: This is the process of eliminating or controlling identified hazards using the hierarchy of controls.

Education and Training: All employees, including management, must be properly trained on safety procedures and hazard recognition.

Program Evaluation and Improvement: The program should be regularly evaluated to see what is working and what needs to be improved. This includes tracking safety metrics and correcting any shortcomings.

Communication and Coordination: This is particularly important for businesses that use contractors or temporary staff.

All parties must communicate and coordinate to ensure a safe working environment for everyone.

3. The Role of an OSHA-Required Poster in the Workplace

The OSHA "Job Safety and Health: It's the Law" poster is a crucial part of an employer's compliance obligations. Its primary role is to inform employees of their rights under the Occupational Safety and Health Act. The poster outlines key employee rights, such as:

The right to a workplace free from recognized hazards.

The right to request an OSHA inspection.

The right to a confidential inspection.

The right to receive information about hazards and injury/illness records.

The right to report injuries and illnesses without fear of retaliation.

The poster must be displayed in a conspicuous place where all employees, including applicants, can easily see it, such as in a break room or near a time clock.

4. How OSHA's Free Consultation Program Helps Small Businesses Achieve Compliance

OSHA's On-Site Consultation Program is a no-cost, confidential service for small and medium-sized businesses.

The program works by having a state-run or university-based consultant come to your workplace to perform a "mock" inspection.

Find and fix hazards: The consultant will walk through your facility with you and your employees to identify both existing and potential hazards.

Give advice for compliance: They will provide expert advice on how to comply with specific OSHA standards.

Establish a safety program: The consultant can help you develop and implement a safety and health management program tailored to your business.

The key benefit is that this service is separate from OSHA enforcement.

5. The Consequences of Non-Compliance with OSHA Regulations

Non-compliance with OSHA regulations can lead to serious consequences, ranging from financial penalties to legal action and reputational damage.

Financial Penalties: OSHA has a range of penalties based on the severity and nature of the violation.

These can include: Serious Violation: A violation where there is a substantial probability of death or serious physical harm, and the employer knew or should have known of the hazard.

Fines can be up to $15,625 per violation. Willful Violation: When an employer knowingly disregards a regulation or acts with plain indifference to employee safety.

Fines can be up to $156,259 per violation. Repeated Violation: A repeated violation of a previous offense.

Fines can also be up to $156,259 per violation.

Criminal Charges: In cases where a willful violation leads to a worker's death, an employer may face criminal charges, including potential jail time.

Other Consequences: Beyond fines, non-compliance can lead to higher workers' compensation insurance premiums, costly legal fees from lawsuits by injured workers, a damaged company reputation, and a decline in employee morale and productivity.