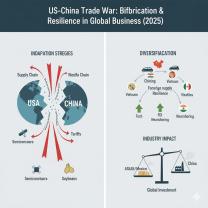

The US–China trade war, far from being a historical footnote, remains the single most important geopolitical factor shaping global commerce and strategic planning in 2025. The initial skirmishes of 2018 have evolved into a complex, multi-front economic and technological competition, forcing multinational corporations to fundamentally reassess their operating models. The shift is permanent: businesses can no longer rely on the seamless, hyper-efficient global supply chain model that defined the previous three decades.

Today, multinational corporations face a daunting landscape characterized by persistent, high-level tariffs, endemic supply-chain disruptions, intensifying investment restrictions—especially in sensitive technology sectors—and a rapidly changing patchwork of regulatory landscapes. Companies are caught between the world's two largest economies, having to decide whether to decouple, de-risk, or localize their operations to navigate this high-stakes environment.

This article provides an analytical, data-driven assessment of the US–China trade war’s impact in 2025. We promise readers a deep dive into the most affected industries, the strategic adjustments global businesses are employing, the chilling effect on investment flows, and the emerging commercial opportunities available to those who adapt most effectively to the current, fragmenting trade climate.

Which Industries Are Most Affected by the US–China Trade War in 2025?

The impact of ongoing trade tensions is not evenly distributed. Sectors characterized by high-volume, interdependent supply chains or those dealing with strategic, dual-use technologies are particularly vulnerable.

Technology and Semiconductors

The technology sector, particularly semiconductors and advanced computing, is at the epicenter of the conflict. The US has used export controls on advanced chips and manufacturing equipment as a primary leverage tool to slow China's technological development, while China has responded by tightening control over rare earth elements and other critical inputs.

Vulnerability: These sectors are vulnerable due to their complex, multi-country supply chains.

US companies like Nvidia and Applied Materials rely on the vast Chinese market for sales and manufacturing, while global electronics giants like Apple and Dell depend heavily on Chinese final assembly (Source: J.P. Morgan, Yale Budget Lab). Example: Chinese restrictions on rare earth exports, which are essential for magnets in electric vehicles, defense systems, and consumer electronics, create significant input risk for Western manufacturers, raising costs and forcing a costly scramble for alternative, non-Chinese sources.

Automotive and Consumer Electronics

The automotive and consumer electronics industries face a direct hit from both tariffs and the rising cost of imported components.

Vulnerability: Auto manufacturers and parts suppliers are highly integrated globally.

The US is heavily reliant on Chinese car parts and accessories. Tariffs on steel and aluminum further inflate production costs across the board (Source: ORI, TBL). Example:Tesla and General Motors have had to adjust pricing and supply chains in response to tariffs on imported components and finished goods.

For consumers, short-term estimates predict motor vehicle prices could rise by over 12% in the short run due to duties on inputs. For consumer goods, companies like Skechers and Crocs have been forced to absorb costs or pass on price hikes due to their reliance on Chinese manufacturing hubs for footwear and apparel (Source: Quartz).

Agriculture

The agriculture sector, primarily US soybeans and pork, remains a frequent target for Chinese retaliatory tariffs due to its political sensitivity in US heartland states.

Vulnerability: China is the largest export market for US soybeans.

Abrupt import bans or punitive tariffs have devastated farm revenues, forcing US producers to store crops and sell at drastically reduced prices while China shifts its sourcing to countries like Brazil and Argentina. This strategic use of an import ban is a direct mirror of Beijing’s use of rare earth exports as leverage (Source: Times of India).

How Are Global Companies Adjusting Their Strategies to Trade Tensions?

Multinational corporations have moved past a "wait-and-see" approach and are now implementing profound, structural changes to build resilience into their supply chains.

| Strategic Adjustment | Description | Countries of Focus (Example) |

| Supply-Chain Diversification | Shifting production and sourcing away from China (the "China+1" strategy) to reduce exposure to tariffs and geopolitical risk. | Vietnam, India, Mexico, Thailand, Malaysia |

| Production Relocation (Nearshoring/Reshoring) | Moving manufacturing closer to the final consumer market (Nearshoring to Mexico for the US market; Reshoring to the US/EU). | Mexico (Automotive/Electronics), Eastern Europe (EU Market) |

| Pricing and Cost Absorption | Companies are employing sophisticated customs strategies, such as inward/outward processing, or absorbing tariff costs to protect market share, often impacting profit margins. | Global Importers |

| Geopolitical Intelligence | Elevating geopolitical risk and regulatory compliance (e.g., rules of origin, export controls) from a legal function to a strategic, C-suite competency. | All MNCs |

| Architecting Regional Resilience | Establishing separate, dedicated production ecosystems for different major markets (e.g., one supply chain for the US/Americas and another for the Asia-Pacific/EU). | Apple, Samsung, Nike (shifting to Vietnam/India) |

Case Study in Adaptation: The Electronics Supply ChainMajor electronics manufacturers like Apple and Samsung have been pioneers in the China+1 strategy.

Will the 2025 Trade Climate Improve for Multinational Businesses?

The trade climate in 2025 remains defined by high volatility, making major long-term strategic decisions incredibly challenging.

Factors Influencing the Trade Climate

Geopolitical Negotiations: While rhetoric can be conciliatory—as seen with occasional signals of openness to a trade deal between the US and China—the underlying structural tensions over technology, Taiwan, and critical minerals remain.

Any "truce" is likely to be temporary and transactional rather than a return to the pre-2018 status quo. Domestic Policy Priorities: The US has doubled down on industrial policies aimed at reshoring manufacturing and securing strategic supply chains (e.g., semiconductors, rare earths) through legislation and tariffs. China is equally focused on self-sufficiency (indigenous innovation) and leveraging its dominance in critical supply chains.

These domestic priorities in both countries make broad tariff reductions politically difficult. Global Economic Conditions: Persistent global inflation, partially fueled by the inefficiencies of bifurcating supply chains, puts political pressure on governments. However, this has not yet been strong enough to override the strategic national security concerns driving the trade war (Source: Tax Foundation).

Scenario Analysis: Short-Term vs. Long-Term Prospects

| Scenario | Short-Term (6–12 months) | Long-Term (3–5 years) |

| Continued Tensions (Most Likely) | High tariff rates persist; more non-tariff barriers (e.g., export controls on critical minerals, port fees) are introduced; market volatility continues. | Economic Decoupling in strategic sectors (Tech, Defense, Critical Minerals) accelerates; global trade fragmenting into regional blocks (US-centric, China-centric). |

| Temporary De-escalation | Limited, targeted tariff reductions (e.g., on consumer goods) to ease inflation or for political optics; focus shifts to negotiated agreements in specific sectors. | Underlying rivalry persists; businesses use the window to accelerate supply chain diversification rather than re-engage with the old model. |

| Escalation | Massive tariff hikes (e.g., 50%+), broad export controls, and increased regulatory pressure (e.g., more entities added to trade blacklists). | Severe market disruption; faster, more forceful reshoring or nearshoring by companies; increased geopolitical risk premium on investment. |

The long-term prospect for multinational operations points to an acceptance of a multipolar trade world, where separate, dedicated supply chains for different regions are the norm.

How Do Tariffs Between the US and China Impact Global Investments?

Tariffs and the resulting uncertainty act as a massive risk premium on foreign direct investment (FDI), particularly for cross-border mergers, acquisitions, and greenfield projects. The primary impact is a redirection of capital away from direct US–China investment and toward third-party countries.

Uncertainty in FDI: The lack of predictability in tariffs and export controls causes firms to delay large-scale projects or joint ventures. Chinese firms have shown a chilling effect on their overall outbound investment, especially by state-owned enterprises (SOEs) (Source: Oxford Academic).

Investor Behavior: Investors are displaying tariff-jumping behavior.

Chinese firms, in particular, are increasing their outward FDI into ASEAN countries (like Vietnam and Thailand) and Mexico. This strategy uses these third countries as "bridges" to access the US market while avoiding US tariffs on goods directly from mainland China (Source: JETRO). Impact on Joint Ventures: The rise in trade tensions has made technology transfer and intellectual property protection a central concern.

While China’s Foreign Investment Law (FIL) in 2020 aimed to simplify the process and signal openness, the US’s aggressive use of export controls and investment screenings (like CFIUS) has counteracted this, making high-tech joint ventures between US and Chinese firms extremely risky.

Sectoral Examples of Investment Shifts:

Automotive/Electronics: Investment in new manufacturing facilities is surging in Mexico (nearshoring to the US market) and Vietnam (ASEAN hub).

Energy: The energy sector has faced significant retaliatory tariffs (e.g., on US coal, crude oil, and LNG), creating investment risk and shifting sourcing patterns globally.

What Are the Emerging Opportunities for Global Businesses Amid the Trade War?

While the trade war creates massive disruption, it is also a powerful catalyst for new investment, innovation, and strategic re-alignment, creating clear opportunities for agile global businesses.

1. Rise of Alternative Markets and Regional Supply Chains

The China+1 strategy is generating immense opportunities for new manufacturing and sourcing hubs.

Vietnam and India: Vietnam, with its cost-competitive production and favorable trade agreements, has seen explosive growth in FDI, particularly in electronics and textiles. India is benefiting from its massive domestic market and government incentives (PLI schemes) to attract global manufacturers, establishing itself as a key alternative in consumer electronics and pharmaceuticals.

Mexico: The most significant beneficiary of "nearshoring" for the US market. Its proximity and the USMCA trade agreement make it an increasingly attractive base for automotive parts, electronics, and light manufacturing aiming to bypass Chinese tariffs.

2. The Reshoring and Local Production Boom

Companies that can successfully bring production home or closer to their final markets benefit from incentives and the ability to market their products as secure, local-origin goods.

Incentives: US, EU, and other governments are offering tax breaks and subsidies to encourage reshoring, especially in critical sectors like semiconductors (e.g., the US CHIPS Act).

Filling the Gap: Businesses that invest in modular design architectures and frugal engineering can rapidly reconfigure operations in response to shifting trade dynamics, positioning themselves to fill gaps left by competitors struggling with complicated Chinese supply networks (Source: WEF).

3. Investment in Traceability and Compliance Technology

As rules of origin become a high-stakes competitive advantage (distinguishing tariff-exempt goods from Chinese-origin ones), technology providers focused on compliance and supply chain transparency are thriving.

Innovative Strategies: Investment in digital tracking, verification protocols, and blockchain-backed traceability is becoming a core competency.

Companies that can prove the non-Chinese origin of their components with certainty gain a crucial advantage with customers and regulators (Source: Thomson Reuters, RMIT Vietnam).

FAQ Section

| Question | Answer |

| Which countries benefit from US–China trade tensions? | Vietnam, India, Mexico, Taiwan, Malaysia, and Thailand are the primary beneficiaries, receiving increased FDI and seeing higher export shares to the US as companies relocate production and diversify supply chains. |

| How quickly can multinational companies adjust supply chains? | Full relocation of a complex supply chain takes 3 to 5 years, as it requires new factories, trained labor, and logistics infrastructure. Shorter adjustments, like changing component suppliers or increasing inventory (stockpiling), can be made in 6–18 months. |

| Are emerging markets gaining opportunities due to the trade war? | Yes. Markets in Southeast Asia (ASEAN), India, and Latin America (Mexico) are actively promoting themselves as alternatives to China, leveraging their large labor forces and free trade agreements to attract global manufacturers. |

| Can businesses completely avoid tariff risks? | Not entirely, but they can mitigate risk through diversification, nearshoring, and meticulous customs strategies (like proving non-Chinese origin). The cost of mitigation (i.e., less efficient supply chains) often becomes a new baseline operating expense. |

| How do tariffs affect consumer prices worldwide? | Tariffs generally increase consumer prices, particularly for automobiles, apparel, and electronics. Companies pass on absorbed tariff costs, logistics expenses, and higher input prices resulting from fragmented supply chains. Estimates show price hikes of over 10% in some categories. |

Conclusion

The US–China trade war in 2025 is a persistent, structural reality that mandates strategic change for global businesses.

To navigate this landscape, successful companies are employing a core set of strategies: aggressively diversifying supply chains into countries like Vietnam, India, and Mexico, elevating geopolitical intelligence as a core competency, and investing heavily in supply chain traceability and regional production models.

While political volatility remains high, and a full return to the pre-trade war era is unlikely, the uncertainty is itself creating opportunities. The winners in the coming decade will not be those who hope for a political resolution, but those who proactively adapt to new trade policies, diversify operations for geopolitical resilience, and capitalize on the new, regionalized ecosystems emerging across the globe. The age of the single, globalized factory floor is over, and the era of the resilient, multi-local enterprise has begun.

TechWatch_2025

on October 13, 2025The article correctly highlights semiconductors as the flashpoint. Export controls are essentially a structural shift, not a temporary tariff. Decoupling is real in high-tech.