What is included in a quality manual?

A quality manual is a document that outlines an organization's quality management system (QMS) and provides a comprehensive guide to its quality policies, procedures, and processes. While the specific content can vary based on the organization and industry, a typical quality manual includes the following components:

Introduction:

- Scope: Define the scope of the quality management system, specifying the products, services, and processes covered.

- Purpose: Clearly state the purpose and objectives of the quality manual.

Quality Policy:

- Present the organization's quality policy, which is a statement of its commitment to quality and customer satisfaction.

- Outline the principles that guide the organization's approach to quality management.

Organizational Structure:

- Provide an overview of the organizational structure, including key personnel and their roles within the quality management system.

- Define lines of communication and responsibility.

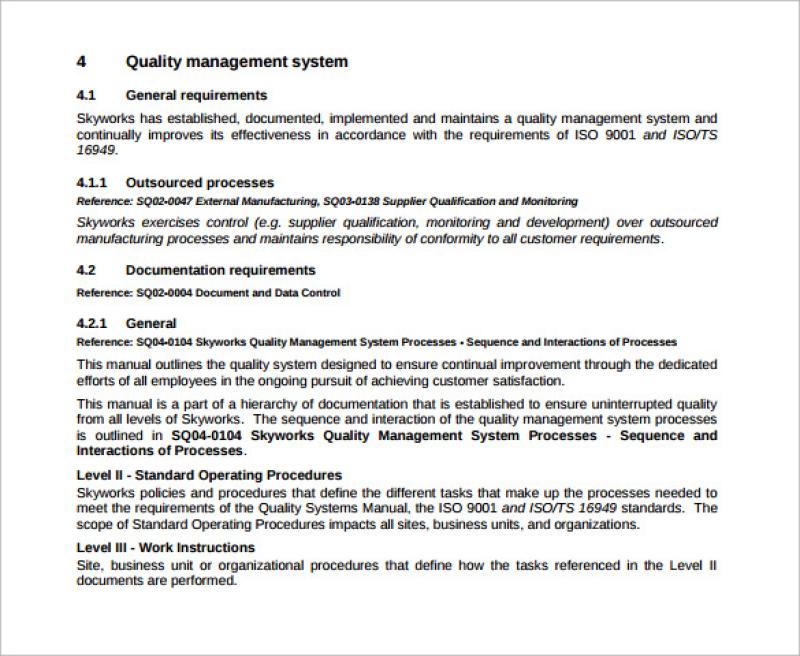

Documentation Structure:

- Outline the structure of the organization's quality documentation, including procedures, work instructions, forms, and records.

- Specify how documentation is created, approved, and updated.

Quality Management System Overview:

- Describe the organization's quality management system, detailing the processes, interactions, and sequence of activities that contribute to the achievement of quality objectives.

- Highlight key components such as planning, implementation, monitoring, measurement, analysis, and improvement.

Quality Objectives and Targets:

- Present measurable quality objectives and targets aligned with the organization's overall goals.

- Specify how these objectives are monitored, measured, and reviewed for effectiveness.

Customer Focus:

- Emphasize the organization's commitment to meeting customer requirements and enhancing customer satisfaction.

- Outline processes for gathering customer feedback and addressing customer complaints.

Management Responsibilities:

- Detail the roles and responsibilities of top management in ensuring the effectiveness of the quality management system.

- Address leadership's commitment to quality and continuous improvement.

Resource Management:

- Cover how the organization allocates and manages resources to support the QMS, including human resources, infrastructure, and work environments.

Product/Service Realization:

- Define the processes involved in the creation and delivery of products or services, from design and development to production and delivery.

- Specify how these processes are controlled to meet quality requirements.

Measurement, Analysis, and Improvement:

- Describe the processes for monitoring, measuring, analyzing, and improving the QMS and its performance.

- Address methods for data collection, analysis, and corrective/preventive actions.

Control of Nonconformities:

- Outline procedures for identifying, documenting, and addressing nonconforming products, services, or processes.

- Specify the corrective and preventive actions taken to eliminate root causes.

Continuous Improvement:

- Emphasize the organization's commitment to continual improvement of the QMS.

- Describe methodologies, such as the Plan-Do-Check-Act (PDCA) cycle, used for ongoing improvement initiatives.

Records Management:

- Define the procedures for creating, maintaining, and disposing of quality records.

- Address the retention period and accessibility of records.

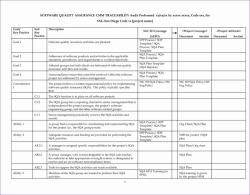

Audit Process:

- Outline the internal and external audit processes used to assess the effectiveness of the QMS.

- Specify how audit findings are documented and corrective actions are initiated.

Appendices and Supporting Documentation:

- Include any additional documentation, flowcharts, or supplementary materials that support the content of the quality manual.

It's important to note that the structure and content of a quality manual should align with the requirements of the relevant quality management standard (e.g., ISO 9001). Organizations may also customize the manual to meet their specific needs and industry regulations. Regular reviews and updates are essential to ensure the manual remains relevant and effective.

1. Typical Sections Included in a Quality Manual

A quality manual is a comprehensive document that outlines an organization's quality management system (QMS). It provides a framework for ensuring that products and services consistently meet or exceed customer requirements. The specific sections included in a quality manual can vary depending on the organization's size, industry, and regulatory requirements. However, some common sections include:

Scope: Defines the scope of the QMS, including the products and services covered, the organizational units involved, and the geographic locations applicable.

Quality Policy: States the organization's commitment to quality and its overall quality objectives.

Management Responsibility: Outlines the roles and responsibilities of management in ensuring the implementation and effectiveness of the QMS.

Resource Management: Describes how the organization manages the resources necessary to achieve its quality objectives, such as personnel, facilities, and equipment.

Product Realization: Details the processes involved in the design, development, production, and delivery of products and services.

Measurement, Analysis, and Improvement: Explains how the organization collects, analyzes, and uses data to monitor and improve its QMS.

Control of Non-Conforming Products: Defines the procedures for identifying, isolating, evaluating, and correcting non-conforming products.

2. Benefits of a Comprehensive Quality Manual for an Organization

A comprehensive quality manual offers numerous benefits to an organization, including:

Enhanced Customer Satisfaction: By consistently producing high-quality products and services, organizations can boost customer satisfaction and loyalty.

Reduced Costs: Implementing effective quality control measures can minimize defects, rework, and waste, leading to cost savings.

Improved Efficiency: A well-defined QMS can streamline processes, eliminate redundancies, and enhance overall efficiency.

Increased Productivity: By reducing errors and rework, organizations can improve productivity and output.

Competitive Advantage: A strong QMS can differentiate an organization from its competitors and attract new business opportunities.

Regulatory Compliance: Adherence to quality standards and regulations can protect an organization from legal and financial liabilities.

Employee Engagement: A clear and accessible quality manual can foster employee engagement and promote a culture of quality within the organization.

Continuous Improvement: The QMS framework encourages continuous improvement and innovation, enabling organizations to adapt to changing market demands and technological advancements.

3. Steps to Create an Effective Quality Manual

Creating an effective quality manual involves a systematic approach that ensures its comprehensiveness, clarity, and relevance:

Establish a Quality Team: Form a team with representatives from various departments to gather input and ensure the manual reflects the organization's overall quality objectives.

Identify Applicable Standards and Regulations: Determine the relevant industry standards, regulatory requirements, and customer expectations that the manual should address.

Gather Existing Quality Documentation: Review existing quality documents, procedures, and policies to ensure alignment and consistency with the manual.

Outline the Manual Structure: Develop a clear and logical structure for the manual, organizing the sections in a way that facilitates easy navigation and information retrieval.

Draft the Manual Content: Assign specific sections to team members with relevant expertise, ensuring consistent style and formatting throughout the manual.

Conduct Internal Review: Circulate the draft manual for internal review and feedback, gathering input from stakeholders across different departments.

Address Feedback and Finalize the Manual: Incorporate feedback into the draft and finalize the manual, ensuring accuracy, completeness, and adherence to organizational standards.

Implement and Maintain the Quality Manual: Distribute the finalized manual to all relevant personnel and provide training on its implementation and use.

Review and Update Regularly: Regularly review and update the quality manual to reflect changes in processes, products, services, standards, and regulations.