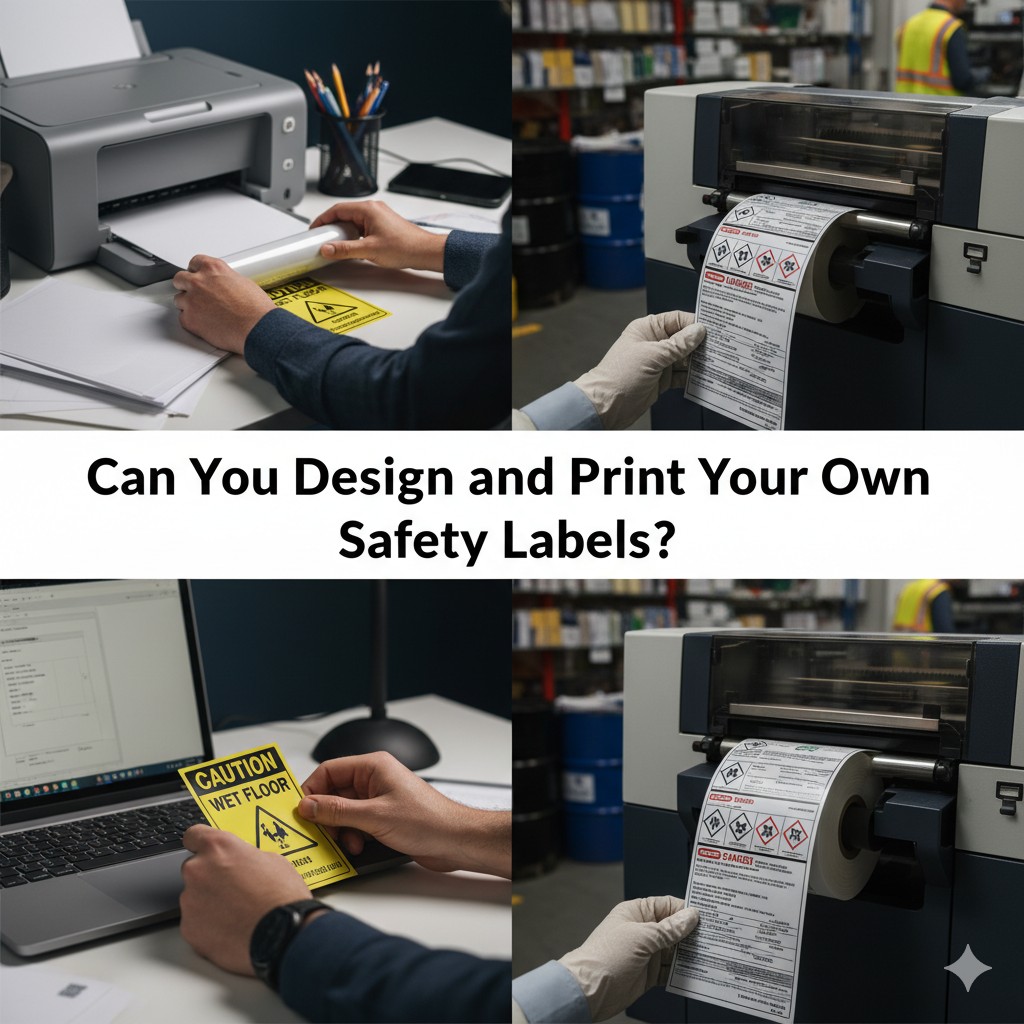

Can I design and print my own safety labels?

Safety is the bedrock of any successful operation, whether you're managing a sprawling industrial plant, running a small business, or simply maintaining equipment at home. At the frontline of protecting workers, consumers, and business assets are safety labels. These small, powerful pieces of vinyl or polyester do the critical job of clearly communicating hazards, necessary precautions, and vital instructions.

In a world where costs are closely monitored and customization is highly valued, many individuals and organizations often ponder a compelling question: Can we design and print our own safety labels? The appeal is clear—the potential to save money, quickly update messaging, or tailor warnings to specific, unique equipment. While the idea of a DIY safety label at home is tempting, the stakes are incredibly high, as the efficacy of these labels is directly tied to regulatory compliance and, most importantly, human safety.

This detailed guide will cut through the uncertainty. We'll walk you through the world of design your own safety labels, exploring the best software tools, practical at-home printing methods, and, crucially, the complex legal requirements for safety labels. By the end, you'll be able to confidently assess whether a DIY approach is a viable solution for your needs or if the precision and compliance assurance of professional safety label printing is the better path.

Can I Design My Own Safety Labels?

The straightforward answer is yes, individuals and businesses absolutely can design their own safety labels. With modern design tools and accessible printing technology, the technical barrier to entry is quite low. However, creating a functional, compliant, and effective safety label is about much more than just putting text on a colored background.

The core of effective safety labeling lies in instant, unambiguous communication. This means your custom design must strictly adhere to recognized international and national standards. You must integrate standard safety symbols—like those outlined by ANSI (American National Standards Institute), OSHA (Occupational Safety and Health Administration), or ISO (International Organization for Standardization)—that are universally understood.

Best Practices for DIY Safety Label Design

Clarity and Contrast: Use high-contrast colors. For example, black text on a yellow background (for warnings) or white text on a red background (for danger) ensures maximum visibility.

Symbol Usage: Always incorporate the appropriate ANSI/OSHA/ISO icons or GHS pictograms (for chemical labels). Never invent a symbol; stick to recognized standards.

Font Choice: Use bold, sans-serif fonts (like Arial, Helvetica, or Franklin Gothic) that are easy to read from a distance and at various angles.

Layering Information: A well-designed label follows a hierarchy: Signal Word (DANGER, WARNING, CAUTION), Symbol/Pictogram, Hazard Statement, and Consequence/Instructional Text.

Durable Materials: While the design is on the screen, the final product must be printed on durable materials such as vinyl or polyester to withstand abrasion, chemicals, moisture, and UV exposure.

What Software Can Be Used To Create Safety Labels?

Choosing the right software is the first critical step in ensuring your custom safety labels are accurate and professional-looking. You have options ranging from general-purpose graphic design software to highly specialized industrial labeling platforms.

General-Purpose Design Tools

These tools are excellent for those with existing design experience or for creating simple, non-regulated labels where complete creative control is necessary.

Adobe Illustrator / CorelDRAW: The industry standard for graphic design. They offer unparalleled precision, vector graphics (which scale perfectly), and the ability to import and manipulate safety symbol libraries. They are best suited for professionals or complex custom designs.

Canva: A more accessible, browser-based tool that offers pre-made templates and an intuitive drag-and-drop interface.

It's great for beginners but may lack the precise measurement and color management required for strict compliance. Microsoft Publisher / PowerPoint: Useful for very simple, internal-use labels, but they are generally not recommended for creating official, compliant safety labels due to limitations in color profiles, symbol libraries, and printing precision.

Specialized Safety Labeling Software

For high-volume printing, integration with a database (e.g., for chemical inventory), or ensuring OSHA/ANSI/GHS compliance straight out of the box, specialized software is the superior choice.

BarTender: A powerful, widely used professional software that connects to databases and includes built-in templates and symbols for compliance with GHS, ANSI, and other standards.

NiceLabel: Similar to BarTender, this software is geared toward industrial labeling and supply chain management, offering extensive regulatory template libraries and centralized control.

Tip for Beginners: Start with a specialized tool that uses templates to guarantee your layout and symbol usage align with compliance standards.

How Do I Print Custom Safety Labels at Home?

The practicality of print custom safety labels at home hinges entirely on the quality of your equipment and materials. A label must be readable and intact for the life of the hazard, which often means surviving extreme conditions.

Printer Types and Materials

| Printer Type | Best For | Pros | Cons |

| Thermal Transfer | High-volume, industrial use, barcodes | Extremely durable, print resists smudging, excellent on vinyl. | Requires special ribbons/media, higher initial cost. |

| Laser Printer | Lower-volume office/general use | Fast, prints well on white polyester/vinyl, affordable per-page. | Toner can scrape off, not ideal for oily or wet environments. |

| Inkjet Printer | Very low-volume, indoor use | Low initial cost, good color output. | Ink is highly susceptible to fading, smearing, and water damage. Not recommended for critical safety labels. |

Recommended Label Materials

The best material choice will be dictated by the environment the label is exposed to:

Vinyl: The most common choice. It is flexible, water-resistant, and good for curved surfaces.

Polyester: Offers superior resistance to high temperatures, chemicals, and abrasion.

Ideal for machinery or harsh industrial environments. Laminated Paper: Only suitable for very short-term, indoor applications (e.g., temporary tagging). Never use for critical, permanent safety warnings.

Step-by-Step DIY Printing Guide

Choose Design Software: Finalize your label design using software that allows for precise output and incorporates compliance symbols.

Select Appropriate Label Sheets: Purchase pre-cut, printable sheets (e.g., adhesive vinyl or polyester) specifically designed for your printer type (laser or thermal).

Test Print: Before using your expensive label sheets, test print the design on regular paper. Hold it up against the actual equipment to check size, font legibility, and color accuracy.

Print Final Labels: Print at the highest quality setting your printer allows.

Apply Lamination: For maximum lifespan and protection against chemicals or abrasion, apply a clear, UV-resistant lamination film over the printed label once the ink/toner is fully set. This step is non-negotiable for labels in industrial settings.

What Are the Legal Requirements for Safety Labels?

This is the most critical section for anyone looking to design and print your own safety labels. A label that looks professional but fails to meet regulatory standards is not only a legal liability but also a genuine safety risk.

Compliance varies significantly by industry and the product being labeled:

OSHA (Occupational Safety and Health Administration): Governs workplace safety in the U.S. They mandate that employers train workers on safety signs and require clear hazard communication.

Their specific requirements are often based on the ANSI Z535 series standards. ANSI Z535 Series: This is the American standard for the design, application, and use of safety signs, colors, and symbols.

Compliant labels must use the specific signal words (DANGER, WARNING, CAUTION, NOTICE) and their corresponding colors and panel layouts. GHS (Globally Harmonized System of Classification and Labeling of Chemicals): If you are labeling chemical containers (including secondary containers), your labels must use the GHS format, which requires specific GHS pictograms (like the skull and crossbones or flame), Hazard Statements, and Precautionary Statements.

ISO (International Organization for Standardization): Used globally, ISO 3864 specifies the internationally recognized safety colors and design principles for safety signs and safety markings.

The Warning of Improper Labeling

A homemade label that is non-compliant, fades quickly, or is illegible can expose your business to severe penalties. OSHA fines for safety violations can be substantial. More importantly, an injured worker or consumer could point to an improper safety label as a contributing factor, leading to catastrophic legal issues and irreparable reputational damage.

Where Can I Order Professionally Printed Safety Labels?

While DIY printing offers flexibility, there are many scenarios where outsourcing your label production is the only responsible option. Professional safety label printing offers a level of quality and compliance assurance that is difficult to replicate at home.

Common Professional Providers

Specialized Safety Label Companies: Companies like Brady, Clarion Safety, or Graphic Products focus exclusively on safety and industrial labeling.

They have libraries of compliant templates and engineers who understand the ANSI/OSHA/GHS standards inside and out. Online Printing Services (e.g., Sticker Mule, Vistaprint): These are good for high-quality, non-regulated labels or simple branding. However, exercise caution: you are responsible for the design's compliance; they will only print the file you provide.

Local Print Shops: Often a good middle ground for small batches. They can provide excellent print quality and advise on durable materials, but they may lack specialized regulatory knowledge.

Advantages of Outsourcing

Professional Quality: Printers use specialized materials like industrial-grade vinyl, polyester, and ultra-durable laminates that are far superior to most consumer-grade stock. They also use specialized thermal or digital printers with UV-resistant inks.

Guaranteed Compliance: Specialized companies can often certify that your label meets all current standards (e.g., ANSI Z535.4-2017). This provides a critical layer of liability protection.

Complex Needs: If you need large batches, serial numbering, or labels that must survive extreme heat, cold, or chemical exposure, professional printing is a necessity.

| Feature | DIY Printing (Home/Office) | Professional Printing (Outsourced) |

| Initial Cost | Low (if you already own a printer) | Zero (pay per label) |

| Per-Label Cost | Variable (media, toner/ink, time) | Lower for large batches; higher for small, custom runs. |

| Quality/Durability | Fair to Good (Requires lamination and quality media) | Excellent (Industrial-grade materials, UV-resistant inks) |

| Compliance Expertise | High Risk (Requires in-house regulatory knowledge) | High Assurance (Often certified compliance) |

| Speed/Flexibility | High (Instant updates) | Low to Moderate (Lead time required) |

FAQ Section

Are homemade safety labels legally valid?

Yes, homemade safety labels can be legally valid if they meet all applicable regulatory standards (like OSHA and ANSI Z535) in terms of layout, size, symbols, signal words, and durability. The legal requirement is the content and material quality, not who produced it. However, because it's so easy for a DIY label to fail on the technical specifications of standards, many organizations opt for professional printing for peace of mind.

What’s the most durable material for safety labels?

For most industrial environments, Polyester or High-Performance Vinyl with a clear, UV-resistant over-laminate is the most durable choice. This combination resists chemicals, abrasion, moisture, and fading from sunlight, ensuring the label remains legible for its intended lifespan.

Can I use a regular printer for industrial-grade labels?

No, not reliably. A standard inkjet printer's ink will quickly fade and smear in industrial conditions. While a good laser printer can be used with compatible polyester/vinyl sheets for indoor/office use, for true industrial-grade labels exposed to harsh environments, a thermal transfer printer or professional UV-cured digital printing is required to ensure the printed message lasts.

How do I know if my labels meet OSHA or ANSI standards?

You must directly reference the ANSI Z535 series standards (especially Z535.4 for product safety signs and labels) and OSHA's 29 CFR 1910 Subpart J and Subpart Z (for chemical labels) requirements. The easiest way to ensure compliance is to use a specialized software that has built-in, pre-tested templates or to consult with a professional safety labeling company.

Conclusion

The journey to design your own safety labels is certainly possible and can be a fantastic way to achieve highly customized, cost-effective solutions for low-risk, non-regulated applications. With the right software, durable print custom safety labels at home is within reach.

However, the question of whether to go DIY or professional always comes down to two absolute priorities: compliance and durability. You must always assess whether a DIY approach fits your needs without compromising safety. For labels that must withstand harsh environments, communicate severe hazards, or adhere to strict regulatory mandates (like those for chemicals or complex machinery), professional safety label printing ensures a robust, compliant product, ultimately providing better safety and legal peace of mind.

Industrial_Ops

on October 04, 2025We primarily use thermal transfer printing, and this article validates that choice for industrial settings. The warning about inkjet printers for safety labels is very necessary—they simply don't last. Good focus on the **durability** aspect, which is often overlooked by first-timers.